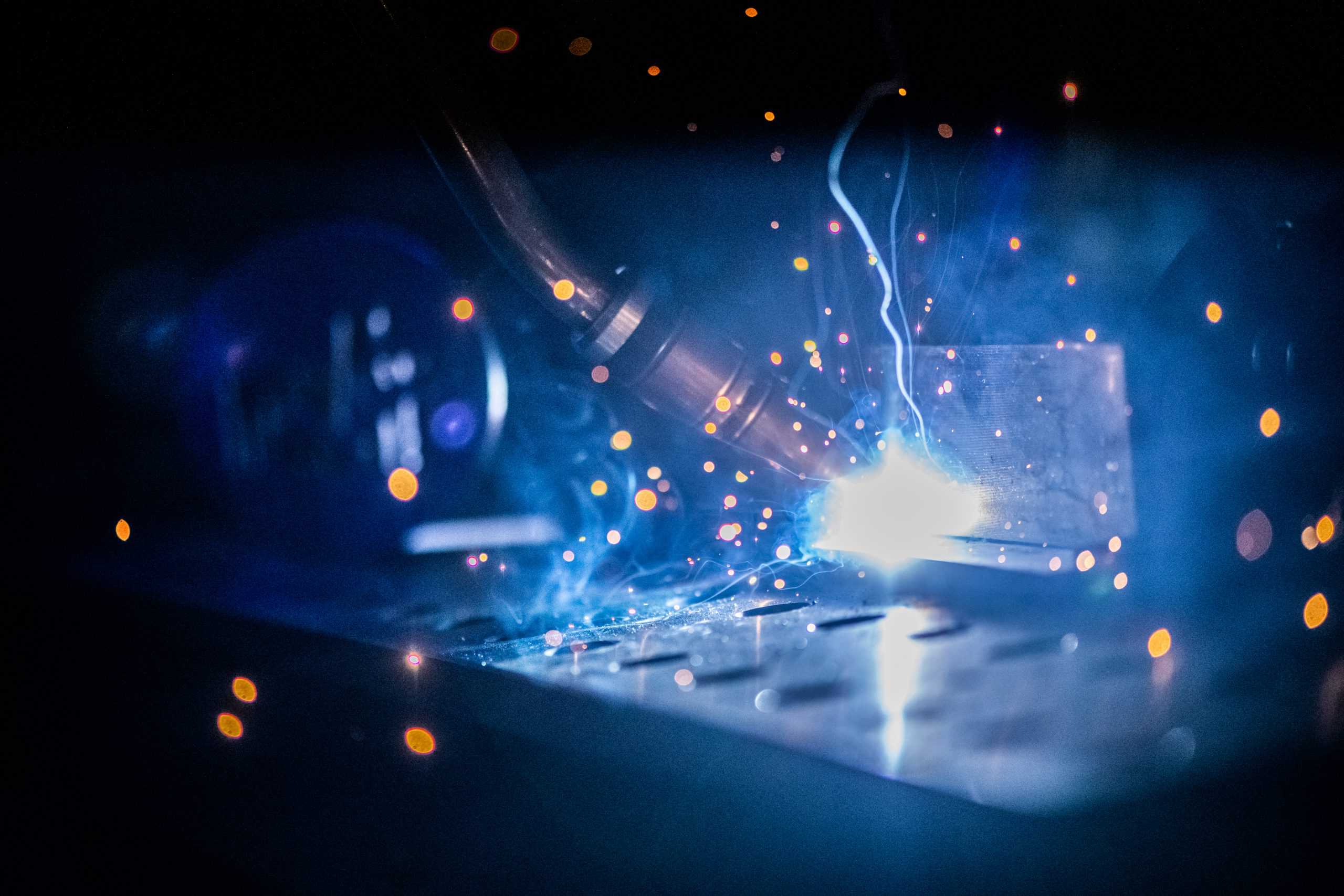

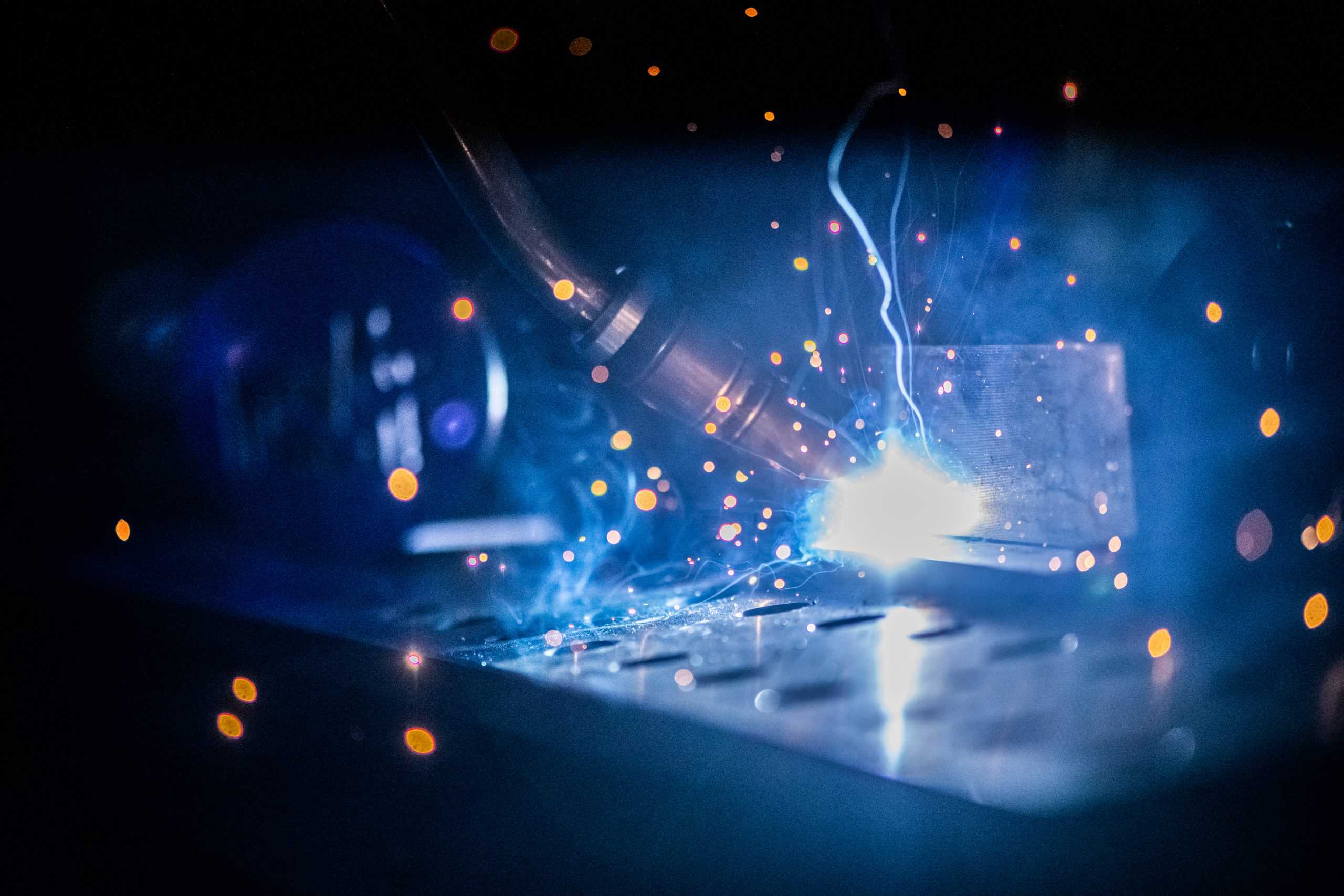

How Laser Welding Works: Definition, Types, Process, and Advantages

Laser welding is a precise and innovative process that utilizes a focused beam of light to fuse metal parts with unparalleled accuracy. This welding technique finds widespread applications across various industries, such as automotive, aerospace, and electronics, where precision and efficiency are paramount.

What Is Laser Welding?

Laser welding employs a directed energy beam to heat and melt workpieces, creating a well-integrated weld. The focused laser beam enables high precision and control over the welding process, resulting in minimal heat-affected zones and reduced material damage. This method is particularly beneficial for welding materials like aluminum, known for their challenging weldability.

Origin of Laser Welding

In the ’60s, laser welding emerged concurrently with laser development. Initial experiments using a ruby laser showcased the precision and minimal heat-affected zones achieved. Laser welding pioneers at Bell Telephone Laboratories pioneered these early successes.

How Does Laser Welding Work?

The technique uses a high-intensity light beam to melt and fuse metal parts, sometimes with additional material from a filler rod. Laser welding machines employ a variety of lasers, such as solid-state, fiber, or CO2, each offering distinct advantages in the welding process.

The Process of Laser Welding

The laser welding process involves crucial steps like part cleaning, precise positioning, beam focusing, power adjustment, and controlled welding motion. Proper joint design, material thickness, and edge preparation are vital for successful laser welding.

Types of Laser Welding

- Conduction Welding: Ideal for thin materials with precise edges.

- Deep Penetration Welding: Suitable for thicker materials requiring deep welds.

- Laser Spot Welding: Perfect for intricate, small parts.

- Laser Seam Welding: Used to create continuous weld seams.

- Hybrid Laser Welding: Combines laser welding with MIG and TIG techniques.

The Advantages of Laser Welding

Laser welding stands out for its precision, speed, versatility, quality, and automation capabilities. It facilitates the creation of clean, strong welds quickly and consistently, making it invaluable in high-tech manufacturing and engineering.

FAQ Section

Does Laser Welding Cost More Than Laser Cutting?

The cost comparison varies based on factors like material type, thickness, and production throughput. Each situation requires individual assessment regarding the cost-effectiveness of laser welding versus cutting systems.

Can Laser Welding Be Performed Without Any Additional Shielding Gas?

While most metals require shielding gas to prevent oxidation and ensure quality welds, some plastics and ceramics can be effectively laser welded without additional protective gases.

What Safety Precautions are Important When Laser Welding?

Safety measures such as eye protection, appropriate PPE, ventilation, training, area control, and fire protection are vital considerations during laser welding to prevent injuries and maintain a safe working environment.

Summary

In conclusion, laser welding presents a cutting-edge welding technology with diverse applications across multiple industries. Its precision, versatility, and quality make it a preferred choice for creating strong and clean welds efficiently.