Quantum Cavities Transform the Way Reactions are Controlled

Quantum Cavities and Their Impact on Chemical Reaction Speeds: A New Frontier in Chemistry

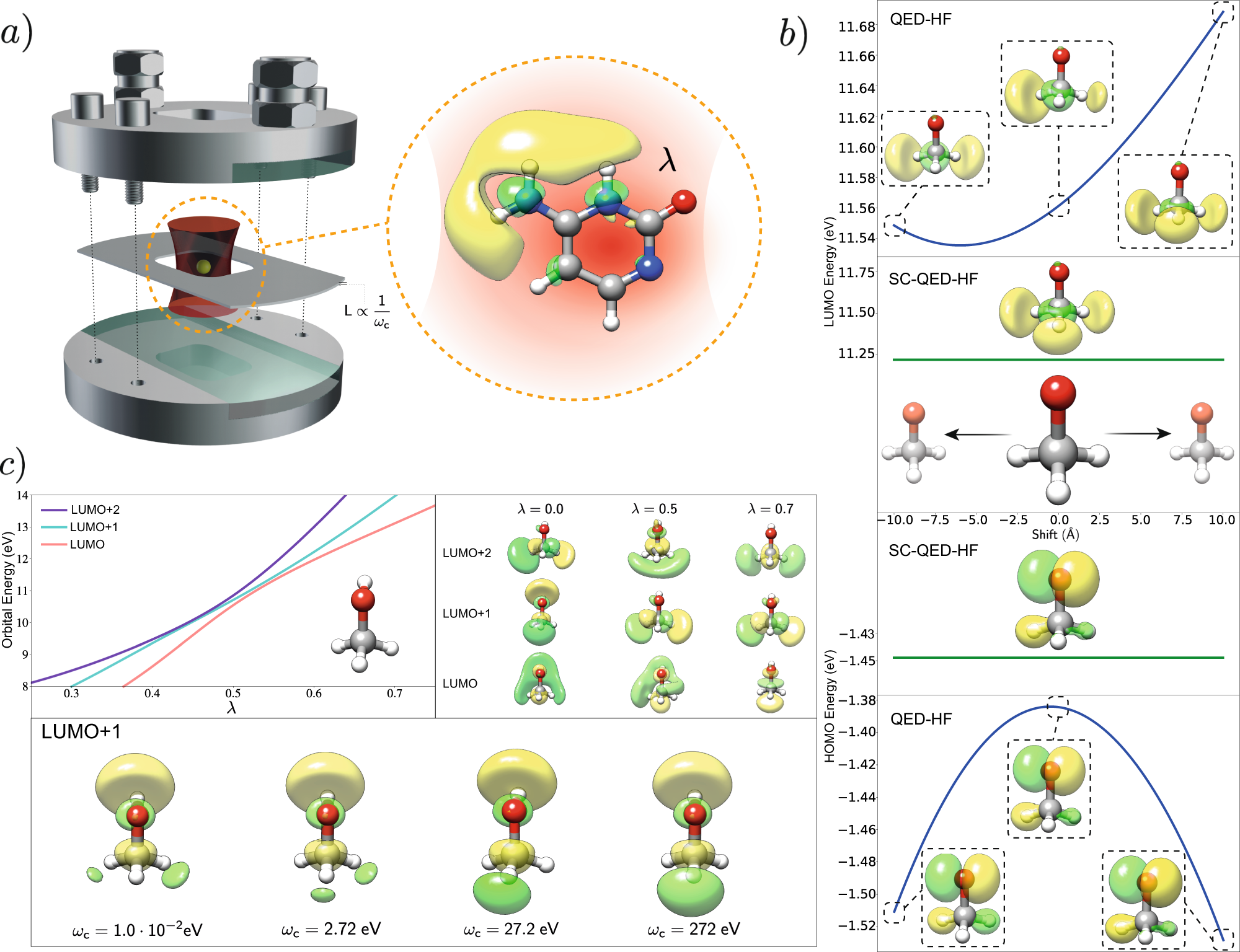

The breakthrough coming out of the University of Rochester marks a turning point in modern chemistry. Researchers have discovered that by placing reacting molecules inside extremely small gaps between gold-coated mirrors, they can speed up or slow down chemical reactions without the need for heat, light, or extra chemicals. This new approach, based on vibrational strong coupling (VSC), works by altering the invisible quantum environment surrounding the molecules rather than modifying the molecules themselves. In this opinion editorial, we take a closer look at the phenomenon, discuss its potential industries, and explore how it can redefine everything from drug manufacturing to sustainable industrial processes.

Understanding Vibrational Strong Coupling in Quantum Chemistry

Scientists have long relied on physical changes—like applying heat, reducing temperature, or increasing pressure—to influence chemical reactions. What the Rochester team has uncovered is a method to adjust reaction rates by focusing on the quantum environment, offering chemists a new way to control the pace of reactions. In essence, by using an optical microcavity—a gap barely a millionth of a meter across—the researchers managed to trap and shape electromagnetic energy, thereby interacting with the natural vibrations of the molecules.

This discovery challenges our classical understanding that chemical reactions are solely dictated by the molecules involved. Instead, the study underscores the importance of the space the molecules reside in. Similar to how the acoustics of a room influence the quality of music, it appears that the quantum “sound” of a molecular environment can tune the reaction speed. Such an insight opens up a dialogue about rethinking standard synthesis approaches, particularly when many industries are eager to streamline production processes.

Expanding the Horizons of Quantum Reaction Control

At its core, the phenomenon of vibrational strong coupling offers a completely fresh approach to chemical engineering. Researchers claim that by dialing the energy environment inside the microcavity, it is possible to orchestrate the chemical reactions without the messy and often expensive add-ons such as additional reagents or extreme temperature changes.

Critically, this method, if harnessed reliably, stands to make chemical production more energy-efficient, more precise, and potentially less environmentally harmful. Unlike approaches that rely on extraneous energy inputs like heat, VSC could revolutionize how industries manage their energy budgets and lower their environmental footprints.

Quantum Reaction Modulation: A Closer Look at the Underlying Process

The tricky parts of understanding VSC lie in the quantum-mechanical interactions between electromagnetic fields and the molecular vibrations. The research team combined quantum mechanics with large-scale computer simulations to generate a comprehensive theory explaining the process. The theory posits that when molecules are placed in the microcavity, certain combinations of molecular vibrational modes and light fields result in a state of strong coupling, which then adjusts the energy flow within and around the molecules.

This coupling is not about changing the molecules per se; rather, it is about altering the immediate quantum environment. In this context, the reaction speed becomes a function of how energy moves between the molecules and their surroundings, much like adjusting the acoustics of a grand hall alters a musical performance. By adjusting the strength of this coupling, chemists may be able to “dial in” the desired reaction speed—faster or slower—based solely on manipulating the energy environment.

Industrial Relevance and Potential Applications

The potential benefits of this approach extend far beyond theoretical physics and laboratory setups. Industries ranging from pharmaceuticals to advanced materials manufacturing could make tremendous use of this technology. Imagine a future where drug synthesis is more controlled, energy consumption in factories is dramatically reduced, and environmental impact is minimized—all thanks to a deeper understanding of quantum environments.

Some of the industries that stand to gain the most from this breakthrough include:

- Drug manufacturing, where precise reaction control is essential for high-quality production.

- Advanced materials synthesis, with the potential for creating novel compounds under controlled conditions.

- Energy production, where efficient catalytic processes could lower the energy input for chemical reactions.

- Environmental engineering, as energy-saving processes reduce the overall carbon footprint of industrial operations.

Envision a table summarizing the key benefits of employing VSC in industrial processes:

| Potential Sector | Key Benefit | Possible Impact |

|---|---|---|

| Pharmaceuticals | Precise reaction tuning | Enhanced drug purity and reduced waste |

| Advanced Materials | Controlled synthesis environment | Development of novel, high-performance materials |

| Energy | Lower energy inputs in reactions | Reduction in operational energy costs |

| Environmental Processes | Minimal reliance on extreme conditions | Lower greenhouse gas emissions and cleaner production |

This table highlights that by rethinking reaction control at the quantum level, industries could bypass traditional hurdles associated with energy input, processing times, and operational costs.

Economic Implications and Business Opportunities

For small businesses, industrial manufacturers, and those involved in automotive and electric vehicles sectors, innovations like VSC provide a significant edge. Lower energy consumption, better control over manufacturing processes, and the ability to tune reactions without harsh physical changes represent key advances in operational efficiency and cost management.

In an era where business tax laws and environmental regulations are increasingly intertwined with operational practices, the potential to reduce energy use can also translate into considerable cost savings. Such savings might not only reduce operating expenses but also provide a competitive advantage in markets where sustainability is a recognized asset.

Business leaders should take a close look at this emerging technology. Adapting or investing in pilot programs could position companies ahead of the curve, ensuring they are not left behind as production methods evolve. Overcoming the initial intimidating technical aspects of applying quantum-level reaction control may prove well worth the effort in terms of long-term efficiency and reduced environmental impact.

Potential Business Benefits from Quantum-Driven Reaction Control

There are several key benefits that businesses might realize with the integration of this quantum-based control mechanism:

- Enhanced Efficiency: By controlling reaction rates without traditional energy inputs, operational efficiency improves significantly.

- Cost Savings: Lower energy requirements can lead to reduced utility bills and operational costs.

- Environmental Sustainability: Reduced reliance on extraneous energy sources contributes to a lower overall environmental footprint.

- Product Consistency: More precise control over reaction rates can lead to improved product quality and consistency.

Given these advantages, it may soon become a must-have option for companies that want to stay competitive in a market where efficiency and sustainability are increasingly important. As the technology matures and scales beyond the lab, early adopters could see a robust return on investment.

Challenges and the Road Ahead

While the promise of altering chemical reactions by focusing on the quantum environment is highly exciting, it isn’t without its tricky parts. The current demonstration of vibrational strong coupling has only been achieved under tightly controlled lab conditions. Scaling this process to meet industrial production standards is, at the moment, still a nerve-racking challenge. Issues such as maintaining consistent coupling strength across larger reactors and adapting the process to variable production scales are some of the full of problems that engineers and scientists will need to tackle.

Moreover, the process requires fine tuning of the microcavity dimensions and precise control over the electromagnetic environment. For chemists and chemical engineers, these tangled issues represent significant hurdles. However, the ongoing research and robust theoretical foundation provided by the Rochester study offer a promising blueprint for addressing these challenges.

Key challenges identified include:

- Scale-Up Difficulties: Achieving consistent quantum control in larger systems could be tricky when moving out of the controlled lab environment.

- Material Engineering: Designing durable and efficient microcavities that can withstand industrial conditions is a complicated piece of engineering work.

- Cost Considerations: The initial investment in technology that can manipulate reaction speeds at the quantum level might be overwhelming for some small businesses, although the long-term benefits could justify the expense.

- Integration with Existing Processes: Companies will need to find a way to make the transition from conventional methods to quantum-controlled processes without disrupting current production lines.

To manage these challenges, collaborative efforts between academic research institutions, industrial partners, and government bodies will be essential. Funding, policy incentives, and targeted research initiatives are among the key ingredients that could help this technology cross from the laboratory to widespread application.

Environmental and Sustainability Benefits

A major driver for advancements in modern manufacturing is the need to reduce environmental impact. The ability to control chemical reactions by modifying their quantum surroundings aligns well with growing industry and regulatory pressures to reduce energy consumption and lower carbon emissions. Instead of ramping up temperatures or applying additional chemicals—which can sometimes have unintended side effects—this innovative method offers a cleaner, more sustainable alternative.

One of the super important advantages here is that fewer external inputs means less waste and lower energy usage, both of which are critical as companies face increasing scrutiny from environmental regulators. This approach can be seen as a key tool in the arsenal for building a greener industrial future. The fact that this method bypasses many of the conventional approaches that require heating or the addition of potentially harmful reagents translates into a process that contributes less to industrial pollution.

Environmental benefits include:

- Reduced energy consumption due to the absence of extreme heat or pressure requirements.

- Minimized introduction of extra chemicals, which lowers the risk of hazardous by-products.

- Potential for integration with renewable energy sources as the process itself becomes more efficient.

For stakeholders worried about navigating the ever-changing landscape of environmental regulations, this quantum-based control method offers a promising way to achieve sustainability goals without compromising production efficiency.

Adapting to a Sustainable Future: A Business Perspective

Environmental responsibility is transitioning from a buzzword to a business imperative. Companies that are eager to steer through emerging regulations and meet market expectations for greener practices have a unique opportunity to integrate quantum reaction control into their production lines. Here are some ways that businesses could get into this field:

- Research Partnerships: Work with leading universities and research institutions to pilot the application of vibrational strong coupling in a commercial setting.

- Government Incentives: Leverage potential tax breaks or grants aimed at sustainable production methods.

- Process Optimization: Invest in upgrading existing infrastructure to accommodate new quantum-controlled reaction chambers.

- Long-Term Planning: Develop a phased approach to integrate this technology as it matures and becomes more widely adopted.

Technological Innovations and the Future of Synthesis

One of the most exciting aspects of the Rochester study is that it challenges our traditional notions of chemical reactivity. Instead of modifying the substances directly, the focus shifts toward creating a conducive quantum environment that determines how fast or slow a reaction runs. This innovation could herald a new era in synthesis, one where adjusting the invisible settings of a reaction is just as important as the reactants themselves.

In many ways, this discovery can be thought of as being akin to tuning an instrument rather than composing an entirely new piece of music. The subtle details in how energy flows—when combined with state-of-the-art computer modeling and quantum theory—allow for a level of precision that brings chemistry closer to an art form underpinned by rigorous scientific principles. Researchers now have a detailed blueprint of the conditions required for VSC to work, which in turn inspires the development of reaction pathways that account for the energy environment as much as the chemical ingredients.

This approach also presents an intriguing way of dealing with the confusing bits of reaction kinetics that have puzzled scientists for decades. By taking a closer look at the interplay between electromagnetic fields and molecular vibrations, scientists can figure a path through the tangled issues that have long obstructed the predictive power of conventional chemical models.

Bridging the Gap: From Theoretical Physics to Practical Applications

Transitioning from theoretical models to real-world applications is always a nerve-racking process—yet history has shown that many groundbreaking ideas eventually find their footing in industry. At this stage, the vibrational strong coupling method remains primarily confined to the lab. However, its promise is undeniable. By adapting these principles into scaled-up systems, companies can manage to get around the traditional constraints imposed by reaction conditions, such as the reliance on heat or extra reagents.

A strategic roadmap for integrating this technology might involve the following steps:

- Step 1: Pilot Testing – Collaborate with local research institutions to build test systems where reaction rates can be tuned via quantum cavities.

- Step 2: Scaling Up – Once proof-of-concept is established, work on larger systems that mimic industrial production environments.

- Step 3: Process Integration – Gradually integrate quantum-controlled reactors with existing production lines while monitoring for efficiency and quality improvements.

- Step 4: Regulatory Alignment – Ensure compliance with industry standards and environmental regulations by demonstrating the sustainable benefits of the quantum approach.

Comparative Analysis: Quantum Approaches vs. Traditional Methods

It is useful, especially for business owners and industry experts, to compare the traditional methods of reaction control with the new quantum-based strategies. Traditional chemical reactions lean heavily on altering physical states—like applying heat or pressure—to drive or slow reactions. These methods, while time-tested, often come with significant energy costs, potential waste, and reduced sustainability.

In contrast, quantum-controlled reaction modulation via vibrational strong coupling represents a paradigm shift. Instead of manipulating the chemicals directly, the process changes the environment in which they react. To better understand these differences, let us consider a side-by-side comparison:

| Aspect | Traditional Methods | Quantum-Controlled Methods |

|---|---|---|

| Energy Input | High reliance on heat, pressure, or additional reagents | Energy saving by tuning the quantum environment |

| Operational Efficiency | Variable, often limited by physical constraints | Potential for high precision and consistency in reaction rates |

| Environmental Impact | Higher emissions and waste due to extraneous inputs | Lower emissions and minimal waste by avoiding extreme conditions |

| Scalability | Well-established industrial processes | Emerging technology with challenges in scale-up but promising long-term benefits |

This comparison illustrates that while traditional methods remain reliable, the fine points of quantum-controlled processes offer a compelling alternative that could redefine manufacturing paradigms in the future. There are still little twists concerning control and scalability, but by addressing these head-on, industries can look forward to more efficient, cleaner processes.

Implications for the Automotive and Electric Vehicle Sectors

In sectors like automotive and electric vehicles, where both innovation and sustainability are super important, the implications of this quantum-based reaction control are intriguing. For instance, the development of next-generation batteries, new materials for electric drivetrains, or even improved catalytic converters might benefit from the energy and reaction control brought on by vibrational strong coupling.

Consider these specific applications:

- Battery Manufacturing: Precisely controlled chemical reactions could lead to improvements in battery chemistry, potentially enhancing energy density and extending battery life.

- Lightweight Materials: Advanced materials synthesized under controlled quantum conditions might allow for lighter, more efficient vehicles with improved performance.

- Catalytic Processes: More efficient catalysts designed through quantum approaches could help reduce emissions and improve the overall energy efficiency of automotive production.

For manufacturers in these fields, integrating such cutting-edge processes could provide both a competitive edge in the market and a pathway toward greater environmental responsibility. As with other industries, the challenge will be to work through the technical twists and turns of scaling quantum-controlled reactions while maintaining consistent quality and cost-effectiveness.

Synergizing Traditional Automotive Expertise with Quantum Innovations

Automotive professionals have traditionally excelled at managing large-scale production with a focus on reliability, efficiency, and safety. Adding quantum reaction control into the mix might seem off-putting at first, but the potential benefits could be transformative. By investing in research and forming partnerships with quantum science experts, automotive manufacturers can begin to incorporate these innovations in pilot systems. In turn, this could pave the way for novel manufacturing techniques that offer better durability, improved battery performance, and materials that are fine-tuned at the atomic level.

Policy, Regulation, and the Future of Business Tax Laws

The intersection between scientific innovation and business policy is where many transformative changes truly take root. As with any emerging technology, understanding and shaping business tax laws that recognize the value of sustainable, energy-saving processes will be key. Governments worldwide are increasingly interested in supporting technologies that not only drive economic growth but also help achieve environmental targets.

From a policy perspective, if vibrational strong coupling matures as an industrial technology, we might expect to see:

- Tax incentives for companies that adopt energy-efficient production methods.

- Research grants and funding opportunities aimed at scaling quantum-controlled processes.

- Updated industry standards and guidelines that reflect the new state-of-the-art in chemical synthesis.

- Collaborative public-private partnerships to spark innovation at the intersection of quantum physics and industrial chemistry.

Business leaders and policymakers alike should keep a keen eye on these developments. By taking a proactive approach to incorporate this technology, the state and the private sector can jointly pave the way for a future where energy efficiency and economic growth are not mutually exclusive, but rather synergistic partners.

Implications for Small Businesses and Industrial Manufacturers

For small businesses and industrial manufacturers, the prospect of adopting quantum-driven reaction control is both promising and challenging. On one hand, these companies may reap considerable benefits from energy savings, improved process control, and the potential for licensing innovative technologies. On the other hand, the initial integration could be overwhelming given the technical requirements and the need for significant investment in R&D.

A thoughtful approach may include:

- Pilot Projects: Start small with dedicated research projects to understand the applications of VSC in specific processes.

- Educational Initiatives: Invest in training and workshops to help employees get into the new technology and understand its little details.

- Collaboration: Form strategic partnerships with academic institutions or technology start-ups that specialize in quantum applications.

- Long-Term Vision: Consider a phased adoption strategy that integrates quantum-controlled systems gradually, ensuring minimal disruption to existing processes.

Looking Ahead: Future Research Directions and Opportunities

While the current study by the University of Rochester lays a robust foundation for understanding vibrational strong coupling, its real-world implications are not fully realized yet. Researchers are still figuring a path to scale this technology, but the groundwork is laid for many future advancements. One of the most appealing aspects of VSC is that it forces us to reconsider the role of the environment in chemical reactions—a factor long overlooked in traditional chemical engineering.

Future research may focus on many intriguing areas, including:

- Understanding the Fine Points of Energy Transfer: Further research could dig into how energy flows between molecules and their quantum surroundings, potentially unlocking even more precise ways to tune reactions.

- Developing Robust Microcavities: Engineering microcavities that survive industrial conditions and can be manufactured reliably will be a key technical challenge.

- Integrating Quantum Models with Traditional Kinetics: Bridging the gap between conventional chemical kinetics and the quantum approach will create a comprehensive framework for reaction control.

- Exploring New Reaction Pathways: With better control over reaction speeds, entirely new methods of chemical synthesis could emerge, benefiting multiple sectors such as pharmaceuticals and materials science.

Each of these research directions represents a step toward transforming the complex pieces of quantum theory into practical, scalable solutions. The journey from laboratory innovation to industrial application is often riddled with tension and challenges; however, the potential benefits make the pursuit a must-have for industries determined to lead the next wave of technological innovation.

Collaborative Efforts to Advance Quantum Technologies

One promising avenue lies in the synergy between academic research, industrial application, and governmental support. By pooling resources and expertise, stakeholders can make your way through the puzzling bits and tackle the technical challenges that currently stand in the path of scalable quantum-controlled reactions. Key collaborative efforts might include:

- Joint research projects that combine cutting-edge theory with practical experimentation.

- Government-funded initiatives aimed at promoting sustainable industrial practices.

- Industry consortia focused on the development of standards for quantum-controlled processes.

- Workshops and seminars that educate business leaders on the economic and environmental benefits of VSC.

Final Thoughts: A Quantum Leap for Industrial Chemistry

The discovery of vibrational strong coupling as a means to modulate chemical reaction speeds fundamentally changes how we look at chemical processes. Rather than modifying the reactants directly, this approach changes the finely tuned energy environment surrounding them, offering a sophisticated, energy-efficient method to control reactions. Although there are still intimidating challenges—ranging from technical scalability to integration with existing industrial processes—the potential advantages for cost savings, sustainability, and enhanced production efficiency are substantial.

For industries spanning pharmaceuticals, advanced materials, automotive, and even electric vehicles, this breakthrough represents more than just a scientific curiosity. It poses a practical solution to several of the little twists that complicate traditional chemical synthesis. As companies and governments begin to take a closer look at the promising avenues of quantum-controlled reaction modulation, there is hope that new business opportunities will arise from sustained research, legislative support, and cross-sector cooperation.

While uncertainty persists and further research is required to overcome the current challenges of scaling and integration, there is no denying that the vista of chemical synthesis is undergoing a radical transformation. This quantum approach offers a detailed blueprint, inviting industries to reimagine their production processes in a way that not only saves energy and reduces waste but also sets the stage for the next generation of industrial innovation.

Business leaders, policy makers, and researchers alike are encouraged to keep pace with these advancements. Integrating vibrational strong coupling into industrial practice may soon become a critical factor in shaping competitive advantages amid evolving economic landscapes and stricter environmental regulations. In the end, what was once a puzzling quantum effect might well be the catalyst for a greener, more efficient future across a myriad of industries.

As the dialogue between quantum science and industrial manufacturing deepens, the promise of enhanced reaction control—achieved by a sophisticated alteration of the quantum environment—stands to revolutionize not only the way we conduct chemical reactions but also how we conceive of energy use and sustainability in production. With continued research, collaborative efforts, and strategic investments, the transformative potential of quantum cavities in reaction modulation will likely become a cornerstone of modern chemical engineering and industrial efficiency.

From the laboratory breakthroughs at the University of Rochester to the expansive possibilities in industries across the world, this innovative approach to reaction control has already set the stage for a pivotal shift in modern manufacturing. While the journey from theory to widespread application may be loaded with challenges, the rewards of energy savings, improved precision, and a reduced environmental footprint make this quantum leap one well worth taking.

Originally Post From https://interestingengineering.com/science/how-speed-slow-reactions-quantum-cavities

Read more about this topic at

Quantum Control: Becoming Proactive With Chemical …

Rabitz Group: Reaction control in the quantum realm