Blood Pressure Pill Recall Uncovers Hidden Cancer Danger and Sparks Serious Safety Questions

FDA Generic Drug Recalls: A Closer Look at the Teva Prazosin Issue

The recent recall of a generic blood pressure drug, prazosin, by Teva Pharmaceuticals has sparked discussions across the healthcare industry and among patients. The drug, which is used to treat both high blood pressure and post-traumatic stress disorder, was found to contain elevated levels of cancer-causing chemicals known as nitrosamines. In this opinion editorial, we take a closer look at the situation, examine the reasons behind the contamination, and explore what this means for the future of generic drug manufacturing.

In the wake of the recall, there has been considerable debate about the quality controls in place at manufacturing plants and the overall safety of older generic drugs—especially those produced outside of the United States. In this article, we will dig into the reasons behind the incident, review its implications, and offer guidance for patients, pharmacists, and industry stakeholders.

Nitrosamines in Medication: Understanding the Hidden Complexities

Nitrosamines are by-products of many common chemical reactions, forming when nitrite groups interact with amine groups. These compounds appear in various scenarios, from industrial production to everyday food processing. Bacon, pepperoni, and salami, for example, often contain nitrites that can interact with protein compounds to generate nitrosamines.

The chemical reaction between chlorinated water and naturally occurring nitrogen and oxygen compounds also leads to the formation of nitrosamines. Occasional, low-level exposure to these chemicals is generally not considered dangerous. However, concerns arise when exposure is high and prolonged, because a number of studies have linked certain nitrosamines with cancer-causing potential.

It is important to note that while these toxic substances can be found in many everyday sources, the unexpected emergence of nitrosamines in a widely used medication is unsettling. The case of Teva’s prazosin underscores the tricky parts and tangled issues of controlling quality in the generic drug industry.

How Nitrosamines Form: The Science Behind the Reaction

To understand this matter, we need to poke around the fine points of how nitrosamines are formed. Here is a brief overview:

- Chemical Building Blocks: Nitrites and amines are common in various manufacturing processes.

- Industrial Applications: Industries like rocket fuel production and rubber manufacturing can result in high concentrations of nitrosamines during the reaction steps.

- Food Processing: Nitrite preservatives used in cured meats lead to small amounts of nitrosamines.

- Water Treatment: The reaction of chlorinated water with natural nitrogen compounds can yield similar products.

This table summarizes the sources of nitrosamines:

| Source | Description |

|---|---|

| Industrial Processes | High nitrosamine production during chemical synthesis in industries such as rocket fuel and rubber. |

| Food Products | Use of nitrite preservatives in processed meats leading to small quantities of nitrosamines. |

| Water Treatment | Formation of nitrosamines when chlorinated water interacts with natural organic matter. |

Teva Pharmaceuticals and the Recalled Prazosin: Unraveling the Manufacturing Challenges

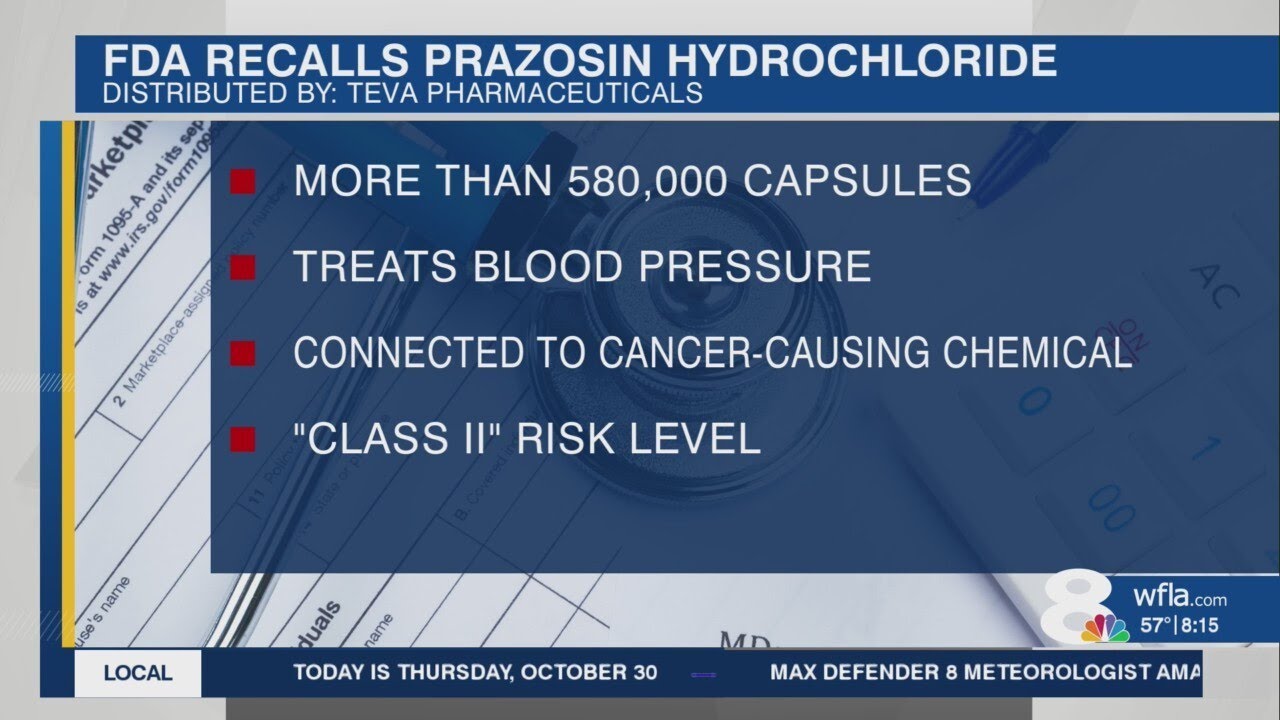

The recall announced by Teva Pharmaceuticals on October 7, 2025, affects more than 580,000 prazosin capsules. This medication, prescribed annually to around 510,000 patients, is just one example of how long-established generic drugs can experience manufacturing glitches as multiple companies join the market. The increased competition due to lower prices in older generics sometimes leads to shortcuts or oversights during production.

While Teva’s prazosin is the only version noted to be contaminated, this incident raises larger, nerve-racking questions about the safety protocols and quality standards in place across the industry. With many generic versions produced by different manufacturers, there are subtle differences in production techniques and oversight that can lead to quality variations. This is especially relevant for drugs that have been on the market for over 25 years.

Competition and Manufacturing: The Impact on Drug Safety

The crowded marketplace for generic drugs creates an environment where lower-priced options naturally become more popular. However, this cost pressure can sometimes lead to compromised quality standards. Consider the following aspects:

- Cost-Cutting Measures: Manufacturers, especially those overseas, may adopt cheaper but less reliable production processes.

- Pressure to Compete: Generics that have a long history are prone to production issues as companies try to undercut each other.

- Quality Assurance: Older medications might lack the modern quality control systems now common in newer pharmaceuticals.

These factors contribute to the challenging bits of ensuring drug safety while keeping prices competitive. The case of Teva’s prazosin is a clear example of how trying to balance affordability with quality can sometimes lead to failure in adequately managing the little details.

Comparing Domestic and Overseas Generic Drug Manufacturing

A controversial aspect of the current debate is whether generic drugs manufactured overseas, particularly in countries like India, pose higher risks compared to those produced in the United States. Recent studies have pointed out that serious adverse events in generic drugs made in India can be up to 54.3% higher than their U.S.-made counterparts.

This difference may be attributed to the mantras of production standards that vary significantly from one region to another. When a medication is available from several sources, the quality may differ based on where and how it is produced. Until recently, it was tricky to figure a path through data from the FDA on these manufacturing plants, since the FDA does not routinely disclose the exact locations or detailed practices of these plants. Advanced analysis of available datasets, however, has started to reveal these hidden complexities.

Key Findings on Overseas Manufacturing Risks

Some of the key considerations in comparing domestic and overseas manufactured generics include:

- Regulatory Oversight: U.S.-based manufacturers tend to operate under more stringent quality control standards, resulting in safer products overall.

- Production Transparency: It is more challenging for pharmacies and patients to know where the product comes from when it is produced overseas.

- Data Limitations: With limited data disclosed by the FDA, it becomes even more overwhelming for stakeholders to assess the real safety records of these medications.

The differences in production quality and regulatory oversight between domestic and overseas manufacturers underscore the importance of having transparent and reliable information that allows pharmacists and patients to make informed decisions about their medications.

Understanding Risk Assessments: What the FDA Classification Means

The FDA has designated the recall of Teva’s prazosin as a Class II recall, which indicates that the medication could cause temporary or medically reversible adverse health consequences. This categorization implies that while the risk is significant, it is not immediately life-threatening. However, this status is still off-putting for patients who rely on such drugs to manage critical health conditions.

To understand the FDA’s classification system, it helps to break down the risk levels:

- Class I Recalls: These are the most severe recalls, where the use of the product can lead to serious health consequences or death.

- Class II Recalls: These represent scenarios where the product could cause temporary or reversible health issues. The Teva prazosin recall falls under this category.

- Class III Recalls: These are the least severe and typically relate to labeling or minor issues that do not pose a major health risk.

While a Class II recall is not the worst-case scenario, it still emphasizes the need for both manufacturers and regulatory bodies to be meticulous in their quality checks and risk assessments to protect patient health.

Steps for Patients: How to Identify and Address a Medication Recall

For patients who rely on prazosin for their health, understanding the recall process and knowing how to verify the safety of their medication is critical. If you’re a patient or caregiver, here are some practical tips to work through this situation:

- Check Your Prescription Label: Look for abbreviations like MFG or MFR, which denote the manufacturer. In the case of Teva, the label might read “MFG Teva” or “MFR Teva.”

- Examine the National Drug Code (NDC): The first four digits of the NDC can identify the distributor — Teva products are usually marked with the number 0093.

- Consult Your Pharmacist: Pharmacists can cross-reference your prescription number with the FDA’s list of recalled lot numbers.

- Do Not Stop Medication Abruptly: Even if your version of prazosin is recalled, discuss any changes with your physician first. The risk associated with a medication lapse might outweigh the potential harm from the recall.

These tips offer a simple method for patients to navigate the confusing bits of recalling and verifying medication safety, ensuring that any decisions made are well informed and supervised by healthcare professionals.

Recommendations for Pharmacists and Healthcare Providers

For pharmacists and healthcare providers, the situation calls for enhanced vigilance and improved processes for managing generic drug recalls. Since generic drugs are increasingly produced by numerous manufacturers, professionals in the field must work to ensure that the medications supplied meet the highest quality standards. Here are several recommendations to help steer through this evolving landscape:

- Enhance Quality Checks: Pharmacies should adopt internal quality assurance measures to verify that their medication supplies comply with the latest FDA guidelines.

- Improve Communication: Healthcare providers must maintain clear lines of communication with patients regarding any recalls or quality issues, explaining the risk assessment and advising on alternative drugs if necessary.

- Stay Informed on Regulatory Updates: As the FDA updates its guidance documents and testing requirements (most recently in 2024), staying current will help providers make safer choices when ordering generic drugs.

- Provide Patient Education: Inform patients about the meaning of recall classifications and the importance of following professional advice regarding their medication use.

By managing your way through these tangled issues, pharmacists and healthcare providers can play a key role in ensuring that patients are not left in the dark about the safety and efficacy of their prescribed medications.

Economic Implications and the Future of Generic Drug Manufacturing

This recall event also holds broader implications for economic news and even industrial manufacturing. There are several connected areas where this incident affects future trends:

- Market Competition and Pricing: As older generics face intense price competition, the pressure to lower costs may inadvertently lead to compromised production quality.

- Manufacturing Trends: With increasing reliance on overseas manufacturers to produce cost-effective drugs, there is a growing risk that cost-saving measures could lead to lowered quality controls.

- Regulatory Responses: Increased vigilance by the FDA and stricter enforcement of quality guidelines are expected in response to these safety concerns.

- Investor Confidence: Incidents such as this can affect investor confidence in pharmaceutical companies, particularly those that fail to maintain consistent quality control across their manufacturing sites.

These economic consequences are far from isolated to the healthcare sector. They are a reminder of how intertwined manufacturing practices, regulatory standards, and market forces are in today’s global economy. As the industry evolves, the balancing act between keeping costs low and ensuring top-notch quality will continue to be a nerve-racking area for regulators, manufacturers, and investors alike.

Balancing Affordability with Quality Control

In the treasury of generic drug production, cost competitiveness is essential. However, when companies cut corners on quality, the fallout can result in recalls, regulatory scrutiny, and, most importantly, risks to patient health. The situation with Teva’s prazosin capsules is a reminder that while affordable medication is a must-have, it should never come at the expense of patient safety.

| Aspect | Challenge | Potential Solution |

|---|---|---|

| Cost Pressures | Lower-priced generics may lead to decreased quality checks. | Implement robust internal quality controls and regular audits. |

| Manufacturing Transparency | Limited FDA disclosure on manufacturing origins makes it hard to assess safety. | Push for enhanced transparency and accessible quality ratings. |

| Regulatory Standards | Variability in international manufacturing practices. | Global harmonization of quality standards through cross-border regulatory collaboration. |

Implications for Future Policy and Industry Standards

Incidents like the current prazosin recall underline the super important need for policy makers and industry leaders to update practices and guidelines. The FDA’s evolving guidelines—from the initial advice in 2021 to the updated version in 2024—are a response to these persistent safety risks. However, more must be done to ensure that quality is not sacrificed in the push for lower prices.

Several steps need consideration at a policy level:

- Enhanced Reporting: Mandate more detailed disclosure regarding the location and practices of manufacturing plants for generic drugs.

- Standardized Quality Metrics: Implement universal quality ratings that can be easily accessed by pharmacies and consumers to compare risks across different manufacturers.

- Incentives for Domestic Production: Encourage domestic manufacturing of generics to help reduce the mixed safety records occasionally associated with overseas production.

- Regular Audits and Inspections: Strengthen the frequency and scope of inspections, especially for plants inherited from long-established generic products.

Throughout these discussions, one must remain mindful that the goal is to keep medications both safe and affordable. The regulatory authorities and the industry are tasked with the tricky parts of ensuring that these objectives are met without overburdening the supply chain or increasing costs to levels that deter access to essential medications.

Looking Ahead: The Role of Technology and Data Transparency

Modern technology and improved data analytics offer promising solutions to many of these problems. As stakeholders dig into the complicated pieces of drug manufacturing, advanced data tracking and transparency platforms can provide the following advantages:

- Real-Time Monitoring: Technology can enable continuous quality monitoring of production processes, catching issues before they lead to contamination.

- Data-Driven Decisions: Enhanced data transparency can allow healthcare providers to compare safety records among various generic manufacturers more easily.

- Improved Communication: Digital platforms can offer more reliable channels for reporting quality issues, enabling quicker responses from both manufacturers and the FDA.

- Patient Empowerment: With more accessible data, patients can have a clearer picture of the medications they use and make informed decisions in consultation with their healthcare providers.

Innovations in this area are not without challenges. Integrating technology in an industry as regulated as pharmaceuticals involves navigating tangled issues, dealing with sensitive data, and ensuring that the advancements benefit all parties—from manufacturers to everyday consumers. Yet, the potential gains in safety and efficiency make this an off-putting challenge worth overcoming.

The Promise of Data Transparency in Improving Drug Safety

Improved transparency can help pharmacies make better choices when stocking generic medications. Although the FDA does publish quality ratings and manufacturing information, the details often lack the granularity needed by pharmacists to fully assess the risk profile of each product. Making data more accessible and understandable would allow for a more informed approach to drug procurement, ultimately benefiting patient safety and confidence in generic medications.

Marketing and Public Perception: Rebuilding Trust in Generics

When a widely used medication like prazosin is recalled due to contamination issues, the impact on public trust can be severe. Patients may become skeptical not only of the manufacturer but also of the entire generic drug market. Rebuilding this trust is a critical challenge that requires coordinated efforts by manufacturers, healthcare professionals, and regulatory authorities.

Several facets contribute to the marketing and public perception of generic drugs:

- Clear Communication: Transparent and easily digestible information about recalls and quality issues is essential for maintaining public trust.

- Educational Initiatives: Campaigns to educate both patients and healthcare providers about the safety measures and testing regimes in place can help demystify the production process.

- Brand Reputation: Manufacturers must work to uphold a reputation for quality, even when faced with cost pressures and competitive challenges.

- Collaborative Efforts: Joint efforts between regulatory bodies and the industry can lead to more robust safety protocols, which in turn should be positively communicated in marketing materials.

Effective marketing strategies in this area need to balance the small distinctions between different generic products, emphasizing that cost savings should not come with a greater risk to health. By reinforcing the message that safety and efficacy are paramount, the industry can gradually reestablish confidence among consumers.

Addressing the Global Impact: How International Trade and Policy Shape Drug Manufacturing

The prazosin recall is not an isolated case but part of a broader, interconnected economic landscape. International trade, business tax laws, and industrial manufacturing processes all play a role in shaping the environment in which generic drugs are produced. As companies seek to deliver affordable medications globally, the twists and turns of international policy and economic strategy become ever more important.

Key international considerations include:

- Trade Regulations: Variations in trade laws can influence where it is most economical—and safe—to manufacture drug products.

- Tax Incentives: Business tax laws can impact manufacturers’ decisions, sometimes favoring cost reductions even if it means lowering quality controls.

- International Quality Standards: Harmonizing quality standards across borders could help reduce subtle differences in safety levels between drugs produced domestically and those made overseas.

- Supply Chain Stability: A stable global supply chain is key to ensuring that drugs are produced and delivered safely and efficiently, even under economic pressure.

These global factors, loaded with issues, require that stakeholders from various sectors come together to manage your way through a highly competitive and interdependent market. With international cooperation and updated policies, the goal would be to create a more transparent and consistent quality landscape for generic drugs worldwide.

International Collaboration for Safer Drug Manufacturing

Promoting international collaboration can be the cornerstone of future policy development. Governments, regulatory agencies, and industry leaders must work hand in hand to develop consistent quality standards and audit practices. Over time, this collaboration could lead to a reduction in the rate of manufacturing issues and recalls, benefiting not just one country but global public health.

Final Thoughts: Balancing Affordability, Safety, and Transparency

The Teva Pharmaceuticals prazosin recall offers a compelling case study of the challenges faced in today’s generic drug market. As we’ve taken a closer look at the feasible reasons behind nitrosamine contamination, we also see that the situation is emblematic of larger issues inherent in a competitive, globalized industry. From the formation of nitrosamines as by-products in chemical reactions to the competing pressures in manufacturing quality and cost, the entire scenario is full of problems that require considered, collaborative approaches.

For patients, there is a clear message: remain informed, verify the source of your medications, and always consult healthcare professionals before making any abrupt changes to your treatment regimen. For pharmacists and providers, the call is to adopt more stringent quality checks and communicate openly with patients. And for policymakers and industry leaders, the challenge is to design systems that balance affordability with uncompromised quality and transparency.

Looking into the future, the rise of advanced monitoring technologies, along with greater data transparency, holds promise for improving manufacturing standards. These innovations can help minimize the tangled issues and risky twists in production, ensuring that generic drugs remain a safe and cost-effective solution for patients everywhere.

Ultimately, addressing these off-putting challenges requires a united effort across multiple fronts—from regulatory authorities and manufacturers to healthcare providers and consumers. A future where affordability does not come at the expense of safety is not only desirable but essential for preserving trust in our healthcare system and supporting public health on a global scale.

Key Takeaways for Stakeholders

To summarize, here are the must-have points that every stakeholder should take away from this episode:

- Understanding Contamination: Knowing how nitrosamines form and the challenges in controlling their levels is essential.

- Quality vs. Cost: The balance between low prices and high safety standards remains a central tension in generic drug manufacturing.

- Comparative Safety: Increased vigilance is necessary, especially when comparing domestic production to overseas manufacturing.

- Patient and Provider Communication: Clear, transparent dialogue is crucial for managing recalls and maintaining trust.

- Future Directions: Embracing technological advancements and enhancing international collaboration can help ease the nerve-racking issues of drug safety.

Conclusion: Shaping a Safer Future in Generic Drug Manufacturing

As we wrap up this discussion on the Teva prazosin recall, it is important to remember that the current incident is a call to action for all participants in the pharmaceutical supply chain. Whether you are a patient, a pharmacist, a regulator, or an industry leader, there are steps you can take to contribute to a system that prioritizes quality as much as cost savings.

The challenges are real and sometimes overwhelming, but with thoughtful collaboration and a commitment to improvement, the goal of providing safe, affordable medicines can be achieved. The path ahead is full of twists and turns, yet each step taken toward greater transparency, rigorous quality controls, and international cooperation is a step toward reducing the risks associated with older generics.

In the end, true progress depends on our ability to manage your way through these complicated pieces of the drug manufacturing puzzle and ensure that the benefits of generic medications—their affordability and accessibility—are never overshadowed by preventable risks.

By continuing to examine issues like the Teva prazosin recall from multiple angles, we can foster an industry that not only meets current needs but also innovates for a safer, more transparent future in pharmaceutical manufacturing.

Originally Post From https://theconversation.com/fda-recall-of-blood-pressure-pills-due-to-cancer-causing-contaminant-may-point-to-higher-safety-risks-in-older-generic-drugs-268968

Read more about this topic at

Is Your Medication Made in a Contaminated Factory? The …

New study finds contaminants in many generic drugs may …