Schneider Electric Sets Sustainability Benchmark as First to Earn UL ECOLOGO Certification

Schneider Electric’s Bold Step in Sustainability Certification

Schneider Electric’s recent achievement of becoming the first company to earn UL ECOLOGO® certification for its energy and industrial automation equipment is sending ripples through the industrial and manufacturing sectors. This certification, awarded for the company’s innovative PowePacT™ Molded Case Circuit Breakers, isn’t just a win for the firm—it’s a harbinger of the dramatic shifts taking place in the way energy-related products are designed, produced, and evaluated. In this opinion editorial, we take a closer look at the transformative nature of this accomplishment, explore the certification’s hidden complexities, and consider what it means for manufacturers, investors, and environmental advocates alike.

For many in the industrial sector, sustainability has shifted from being a mere buzzword to a strategic imperative. Schneider Electric’s move reflects an industry-wide awakening to the importance of validating environmental performance using concrete, science-based benchmarks. As the market faces tricky parts and tangled issues regarding balancing performance with environmental responsibility, the new UL ECOLOGO certification serves as a guidepost to ensure that products not only meet rigorous safety and efficiency standards but also contribute to a cleaner, more sustainable future.

Schneider Electric’s Environmental Innovation: A New Benchmark for Transparency and Accountability

The recent certification by UL ECOLOGO exemplifies a significant milestone in environmental innovation. Schneider Electric has not only met but exceeded a series of stringent criteria that cover the entire product lifecycle—from materials sourcing to end-of-life recyclability. By setting a new standard for transparency and accountability in manufacturing, the company is proving that even in sectors known for their nerve-racking industrial challenges, there is room to lead with environmentally responsible design.

This certification is a testament to Schneider Electric’s commitment to sustainability. In an era where industrial manufacturers are under increasing pressure to reduce environmental impact without compromising performance or reliability, the company’s pioneering spirit is worth celebrating. Its approach demonstrates that with a science-based, comprehensive evaluation system like UL ECOLOGO, industrial players can confidently deploy lower-carbon energy technology at scale. This achievement marks a turning point in the industrial automation sphere, one where environmental stewardship and innovative design go hand in hand.

Dissecting the ECOLOGO Certification Criteria: The Fine Points of Sustainable Industrial Equipment

The UL ECOLOGO certification program represents a voluntary, multi-attribute, lifecycle-based ecolabel that sifts through the subtle parts of environmental and human health impacts. It distinguishes itself through a set of clearly defined criteria that help stakeholders understand the environmental footprints of various products. Let’s take a look at the key criteria:

- Materials: Emphasis on recycled content, sustainably sourced inputs, and the use of bio-based components.

- Manufacturing and Operations: Focus on renewable energy use, energy efficiency measures during production, and effective waste minimization strategies.

- Health and Safety: Reduction of toxic substances and a priority on mitigating hazards that affect human health.

- Product Lifecycle: Assessment of performance, durability, and the potential for recyclability at the end of the product’s useful life.

- Corporate Governance: Evaluation of sustainable practices at the corporate level, ensuring that the commitment to sustainability is embedded across the board.

- Transparency: Mandatory public disclosure of a third-party certified carbon footprint which bolsters accountability and trust.

To further clarify, the table below offers an overview of the major certification elements along with a brief explanation of their significance:

| Certification Element | Details |

|---|---|

| Materials | Emphasis on recycled, bio-based, and sustainably sourced materials to lower environmental footprint. |

| Manufacturing & Operations | Implementation of energy-efficient production techniques, use of renewable energy, and active waste reduction processes. |

| Health & Safety | Mitigating toxicity and ensuring safe industrial practices, thus protecting workers and end-users. |

| Product Lifecycle | Focus on durable, high-performance products that are also easy to recycle and maintain throughout their lifespan. |

| Corporate Governance | Incorporating sustainable practices and transparent reporting across the entire organization. |

| Transparency | Public disclosure and independent evaluation of the product’s carbon footprint. |

This structured and science-based approach is both a promise and a challenge—it promises a more environmentally friendly future while also challenging industry leaders to rethink how they design, produce, and manage their operations.

The Ripple Effects on Industrial Manufacturing and Energy Technology

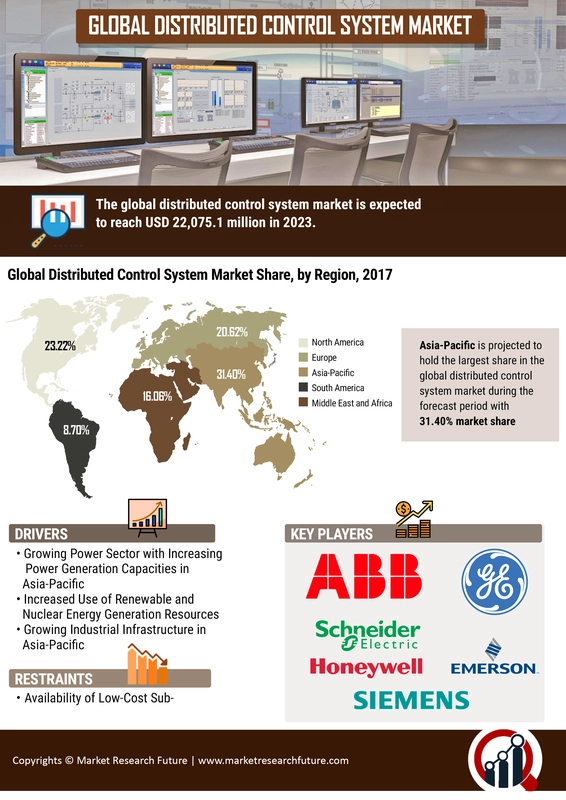

Schneider Electric’s pioneering action reverberates far beyond just its operational sphere. In the realm of industrial automation and electric vehicles—a field where every component must meet exacting standards—the achievement of UL ECOLOGO certification is super important. It sends a strong message: sustainable practices in manufacturing can coexist with high performance and reliability. It is a call for other manufacturers to take similar steps and for regulators to encourage higher standards that emphasize accountability and transparency.

The certification’s success also underlines the importance of public trust in industrial products. In markets where industrial manufacturers are often required to find their way through confusing bits of regulatory requirements and evolving consumer expectations, having third-party verification makes a world of difference. This initiative is a prime example of how detailed, science-based evaluation can make these tricky parts more manageable and less overwhelming.

Low-Carbon Technology: A Game Changer for Energy and Industrial Automation

The shift towards low-carbon energy technology is one of the key drivers behind the growing acceptance of sustainability certifications like UL ECOLOGO. Schneider Electric’s certification represents not only a milestone for the company itself but also an industry-wide acknowledgment of the need for sustainable energy practices. By demonstrating that industrial automation products can be both environmentally and technologically advanced, Schneider Electric is paving the way for a future where low-carbon technologies become the new norm.

Here are a few reasons why low-carbon technology is critical for the energy sector:

- Environmental Impact: Lowering carbon footprints helps reduce the overall impact on climate change.

- Operational Efficiency: Energy-efficient products often consume less power and require less maintenance, resulting in cost savings over time.

- Regulatory Compliance: As governments worldwide tighten regulations on emissions and waste, companies with certified products are better positioned to comply.

- Market Differentiation: Products that meet high environmental standards often enjoy enhanced market credibility and are favored in public and private sector procurement processes.

The move by Schneider Electric is a clear indicator that the future of industrial manufacturing hinges on the successful integration of sustainable practices. This isn’t merely about meeting regulatory requirements—it’s about redefining what’s possible when environmental responsibility is truly taken into account.

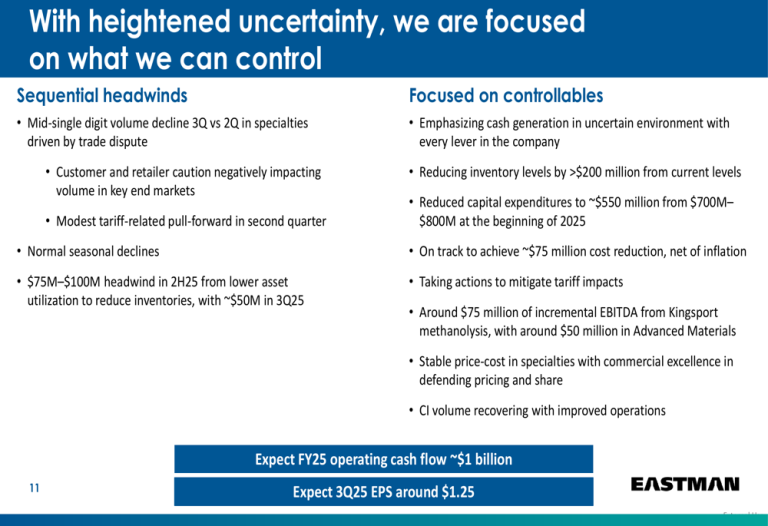

Investing in Sustainability: Implications for Investors and Market Stability

Historically, many investors have been reticent to back companies perceived to be on the nerve-racking side of environmental accountability. However, Schneider Electric’s certification is a reminder that sustainable business practices are not just good for the planet—they’re also sound investments. With validated approaches like UL ECOLOGO certification in place, there is a growing confidence among stakeholders that certified companies are less likely to incur unexpected liabilities or face compliance issues that could damage their profitability.

Investors increasingly recognize the long-term benefits of sustainability, including:

- Risk Mitigation: Companies that adopt stringent environmental standards are less likely to fall foul of sudden regulatory changes or public relations scandals related to sustainability issues.

- Market Resilience: Sustainable companies often show better resilience during market downturns as they are perceived to have a lower risk profile.

- Future Growth: As consumer preferences shift towards environmentally responsible products, companies at the forefront of sustainability are more likely to tap into new market opportunities.

While investor sentiment can sometimes be swayed by market hype and overly technical disclosures, what Schneider Electric’s accomplishment really highlights is the importance of a strong, transparent foundation. With a clear, third-party validated certification, investors have solid evidence that the company’s product innovation is backed by science and good governance practices.

Transparency in Manufacturing: Why Clear, Science-Based Evaluations Matter

The UL ECOLOGO certification program offers a roadmap for both manufacturers and consumers to see the small distinctions that separate sustainable products from the rest. In traditional industrial manufacturing, the subtle parts of production often remain shrouded in mystery, making it hard for customers and regulators alike to truly understand the environmental impact of a product. This certification unpacks those hidden complexities by emphasizing transparency through a series of well-defined, science-based criteria.

Transparency isn’t just about checking regulatory boxes—it’s about establishing trust. When companies like Schneider Electric place their products under the microscope of independent evaluation, they send a clear message: authenticity and accountability are not negotiable. For manufacturers, this means rethinking their processes and finding innovative ways to reduce waste and pollution throughout all stages of production.

Moreover, transparent practices help companies quickly weed out the confusing bits of ambiguity around how products are rated, thereby allowing both customers and investors to figure a path through the myriad of choices in the market. This clarity is critical in an era where the distinction between good and great industrial products often hinges on those fine shades of environmental performance.

Challenges and Opportunities amid a Shifting Industrial Landscape

While Schneider Electric’s achievement is a major milestone, the broader shift toward environmentally responsible manufacturing is not without its nerve-racking challenges. The transition to sustainable practices in industrial manufacturing is full of problems that require companies to tackle everything from outdated production methods to supply chain complexities. For many firms, finding the balance between maintaining competitive performance and integrating sustainable design is an overwhelming task.

Despite these challenges, there are several opportunities that emerge when companies commit to sustainable practices:

- Market Leadership: Early adopters of comprehensive sustainability certifications can set themselves apart as leaders in an increasingly competitive market.

- Customer Trust: Transparent certification processes like UL ECOLOGO help build stronger relationships with customers who are in search of accountability and quality in the products they use.

- Regulatory Advantage: Companies that proactively adopt rigorous environmental standards are often better prepared to manage evolving regulatory landscapes and avoid costly compliance issues.

- Innovation Boost: The drive to meet sustainability criteria frequently inspires internal innovation—leading to improved product performance and operational efficiencies.

To illustrate these dynamics further, consider the following comparative table that highlights traditional manufacturing practices versus those adopted by companies with verified sustainability certifications:

| Aspect | Traditional Manufacturing | Sustainable Certification Approach |

|---|---|---|

| Materials | Primarily virgin materials, with less focus on sourcing | Emphasizes recycled and sustainably sourced inputs |

| Energy Use | High energy consumption without renewable sources | Focus on renewable energy and increased energy efficiency |

| Waste Management | Limited waste minimization processes | Systematic waste reduction and recycling programs |

| Product Lifecycle | Shorter life spans with limited recyclability | High durability, performance, and potential for recycling |

| Transparency | Opaque processes with minimal third-party validation | Clear, third-party verified public disclosures |

This clear contrast not only underscores the benefits of a sustainable approach but also highlights the pressing need for industry-wide changes. Companies that are able to find their way through these tricky parts today are likely to secure a competitive advantage in tomorrow’s market.

What Schneider Electric’s Certification Means for Stakeholders

At its heart, Schneider Electric’s breakthrough is as much about smart business strategy as it is about environmental responsibility. For corporate leaders and investors, the certification serves as a key signal that environmental performance matters—a signal that increasingly influences decision-making processes across the board. This isn’t merely a superficial accolade; it’s a tangible demonstration of how technology and thoughtful design can work together to create robust, sustainable products.

For engineers, product designers, and R&D teams, the certification is a call to dig into the fine details of product innovation. It challenges them to address the subtle parts of production that are often overlooked, encouraging them to adopt a more holistic view of product development. In doing so, the industry can begin to untangle the mixed signals that sometimes make it difficult to reconcile sustainability with industrial performance.

Schneider Electric’s proactive stance offers several lessons for various stakeholders:

- For Manufacturers: It is super important to embed sustainable practices early in the design process. By doing so, companies can reduce exposure to later stage regulatory risks while adding value for customers who are increasingly environmentally conscious.

- For Investors: Companies that muster third-party validations like UL ECOLOGO represent less of a gamble—they are backed by clear, verifiable standards that reduce uncertainty and build long-term market trust.

- For Regulators and Policy Makers: The move offers a tangible model of how industries can meet the set standards without compromising performance. This encourages more consistent policies across the board, resulting in an even playing field for companies that make such investments in innovation.

- For Environmental Advocates: Certifications such as these provide leverage in advocating for greater corporate transparency and accountability, while also highlighting the potential for technology to drive positive environmental outcomes.

The Role of Business Tax Laws and Economic News in Promoting Sustainability

Even as companies strive to integrate environmentally friendly practices into their industrial processes, broader macroeconomic elements such as business tax laws and evolving economic news play a super important role in shaping the landscape. Governments are increasingly looking at tax incentives and support measures designed to lower the cost of investing in green technologies. In many respects, Schneider Electric’s achievement comes at a time when policymakers are actively searching for tangible examples of environmental leadership in industries known for their nerve-racking operational demands.

Evolving tax laws that favor sustainable practices further underscore the financial advantages of adopting rigorous certification. Tax credits, depreciation benefits, and incentives for using renewable energy sources are a few examples of how the synergy between government policies and corporate innovation is set to create a more favorable business environment for firms that invest in eco-friendly technologies.

Economic news and market trends also suggest that industries which proactively tackle the confusing bits of compliance and certification may secure a larger share of the market. As news outlets frequently highlight successful sustainability initiatives, investors and customers alike are beginning to steer their purchases and investments toward companies with a proven record of environmental responsibility.

Future Perspectives: The Green Road Ahead for Industrial Manufacturing

Looking forward, the future of industrial manufacturing and energy technology is poised for dynamic change. Schneider Electric’s achievement is likely only the first step in an evolving journey where sustainability and performance are no longer mutually exclusive. With environmental regulations tightening and market competition intensifying, companies that are able to manage their way through these tangled issues will likely claim a larger share of the market.

One important take-away is that the green road ahead is as much about continuous improvement as it is about reaching a destination. As technology evolves and new materials emerge, the criteria for sustainability may become even more precise. Companies will need to remain agile, ready to digest new regulations and find their way around the small distinctions in product design and environmental impact. This ongoing process will not only help companies maintain compliance but also bolster their image as responsible corporate citizens.

Moreover, as more companies begin to follow in Schneider Electric’s footsteps by seeking certifications like UL ECOLOGO, the overall standards of quality and environmental responsibility will rise. This collective action has the potential to drive significant positive change across global supply chains, ultimately leading to reduced environmental footprints and a stronger push towards renewable energy adoption.

Industry Stakeholder Reactions and Market Dynamics

Initial reactions to Schneider Electric’s certification have been largely positive among industry stakeholders. Social media platforms and industry blogs are abuzz with discussions about the potential ripple effects of this achievement. Business leaders, technical experts, and environmental advocates are all taking a closer look at how such certifications could redefine competitive landscapes in industrial manufacturing.

Many argue that this move will trigger a shift in market dynamics. As companies face the nerve-racking task of meeting the rising expectations of regulators and customers alike, certifications such as UL ECOLOGO may well become the new norm. As these standards become more widespread, companies that fail to adapt might find themselves struggling to secure lucrative contracts or maintain investor confidence.

In this context, the achievement by Schneider Electric can be seen as both inspirational and cautionary. It demonstrates the tangible benefits of integrating sustainable practices right from the product design stage. Simultaneously, it serves as a reminder to other players in the industry that evolving consumer and regulatory expectations are here to stay—and that the cost of ignoring these trends may be steep in the long term.

Key Takeaways for Manufacturers, Investors, and Environmental Advocates

Drawing from Schneider Electric’s groundbreaking certification, several key takeaways emerge for all stakeholders involved in the industrial manufacturing ecosystem:

- Adopt a Science-Based Approach: Relying on clear, empirical data to measure sustainability performance helps eliminate the trickier parts of subjective environmental claims.

- Emphasize Transparency: Public disclosure of environmental metrics reassures stakeholders and builds trust that extends across entire supply chains.

- Prioritize Long-Term Value: Companies that invest in sustainable technologies today are likely to reap economic and reputational benefits in the years to come.

- Stay Agile in a Changing Regulatory Climate: Adapting quickly to new rules and evolving standards is essential for maintaining competitive advantage.

- Balance Performance and Sustainability: Industrial products can achieve high performance while still adhering to rigorous environmental benchmarks—a balance that is super important for the future of the sector.

Conclusion: Embracing the Future of Sustainable Energy and Industrial Design

Schneider Electric’s pioneering achievement in earning UL ECOLOGO certification for its energy and industrial automation equipment marks a pivotal moment for the industry. The company has not only managed to navigate the maze of tricky regulatory requirements and challenging product designs but has also set a benchmark for others to follow in the pursuit of environmental excellence. As the world moves toward a sustainable future, such achievements underscore the fact that environmentally responsible manufacturing is not just a lofty goal—it is an ever-evolving, essential part of modern business strategy.

The interplay between innovative industrial design, science-based evaluation, and clear transparency offers an inspiring model for companies grappling with the subtle parts of sustainable development. Whether you’re an investor assessing market risks, a manufacturer trying to figure a path through changing regulations, or an environmental advocate pushing for greater corporate responsibility, the lessons from Schneider Electric’s experience are full of practical insights.

Looking ahead, it is obvious that the industrial world is on the precipice of change. A deeper focus on low-carbon, environmentally responsible products is not just a passing trend—it’s a robust strategy that will define the future of energy technology. As companies work through the nerve-racking challenges of retooling manufacturing processes, the strategic benefits of this approach become increasingly clear. Schneider Electric’s recent validation via the UL ECOLOGO certification isn’t merely a badge of honor; it is a call to action for the entire sector.

With economic policies, tax incentives, and ever-evolving regulatory frameworks backing the move towards sustainability, the stage is set for a future where every product is designed with an eye for both performance and environmental responsibility. As companies continue to poke around and refine the little details of their product designs, the industry’s future looks promising—a future where innovation, transparency, and sustainability are not mutually exclusive but are integrated into the very fabric of everyday operations.

In wrapping up this assessment, it’s essential to recognize that while the road ahead may be full of problems and nerve-racking twists and turns, the potential benefits are too significant to ignore. Schneider Electric has provided a roadmap for balancing the demands of rigorous industrial performance and green innovation. For the broader business community, this is a must-have blueprint for crafting a resilient, forward-looking, and environmentally sound strategy that caters not only to market demands but also to the global imperative for sustainability.

As more companies adopt similar practices and third-party certifications become a standard measure of credibility and performance, the industrial landscape will undoubtedly transform. The message is clear: adaptability, transparency, and a steadfast commitment to sustainability are keys to long-term success in a highly competitive market. Whether you’re aligning your portfolio with forward-thinking manufacturers or pushing for policy reforms that reinforce these developments, the achievement by Schneider Electric offers a compelling case study in how technology and environmental stewardship together can shape the future of industrial automation and energy management.

Embracing the future means taking the wheel and being unafraid to steer through the intricate yet promising route of sustainable growth. Schneider Electric’s milestone is not just a celebration of present achievements, but also an invitation to all industry participants to join in a collective movement toward a greener, more transparent, and more innovative era in manufacturing.

Ultimately, the path forward is clear: by prioritizing science-backed evaluations, transparent processes, and a commitment to low-carbon technology, the industrial sector can overcome even the most overwhelming challenges. Investors, regulators, and manufacturers alike now have a tangible example of how well-thought-out, sustainable practices can deliver tangible benefits—ushering in an era where environmental responsibility and industrial excellence go hand in hand.

Originally Post From https://www.morningstar.com/news/pr-newswire/20251118ne27601/schneider-electric-becomes-first-company-to-earn-ul-ecologo-certification-for-energy-and-industrial-automation-equipment

Read more about this topic at

Accor Celebrates 200 Hotels Achieving Eco Certification …

Global EcoTraveling Eco-Certification