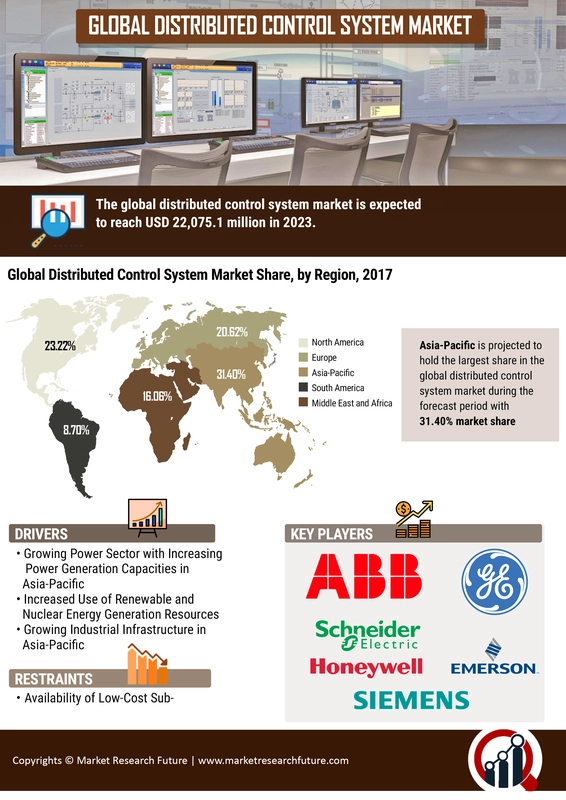

EOS Unveils Extended Metal Powder Family With Four New Alloys

Innovations in Metal 3D Printing: EOS’s Strategic Expansion of Alloy Offerings

The world of metal additive manufacturing has been evolving at a rapid clip, and one of the most exciting developments today comes from EOS GmbH. In its latest move, the company has added four new metal powders to its portfolio – an initiative that offers a fresh set of options for industries ranging from aerospace and automotive to chemical processing and marine applications. In this opinion editorial, we take a closer look at how these new alloys can change the way manufacturers find their path through the sometimes tricky parts of design and production.

Adding New Flavors: A Detailed Look at EOS’s Four New Alloys

EOS has introduced EOS FeNi36, EOS NickelAlloy C22, EOS Steel 42CrMo4, and EOS StainlessSteel 316L-4404. Each alloy brings a unique blend of properties that address very specific requirements encountered in high-stakes industries. Let’s dig into what sets each substance apart and why these new additions are critical for modern additive manufacturing.

EOS FeNi36: Unmatched Thermal Stability for Precision Applications

Designed with aerospace, space, defence, and energy applications in mind, EOS FeNi36 is a game-changer when it comes to precision and dimensional stability under fluctuating temperatures. With a very low coefficient of thermal expansion – performing at less than 2 ppm/K within the 30°C to 150°C range – this alloy is engineered to deliver up to ten times lower thermal expansion compared to widely used alloys like 316L or MS1.

This level of stability is key for components that must maintain fine tolerances despite temperature shifts. Typical applications include:

- Optical housings and mirror mounts

- Cryogenic instrument components

- Optical benches

- Precision metrology inserts

- Small composite tooling inserts

EOS FeNi36 is optimized for the EOS M 290 AM machine and is already commercially available. Its low thermal expansion plays a super important role in reducing the nerve-racking challenges of maintaining alignment and precision in advanced operations.

EOS NickelAlloy C22: High Strength and Extreme Corrosion Resistance

In environments where contact with biological or chemically aggressive media is unavoidable, EOS NickelAlloy C22 steps up as a solution loaded with strength, toughness, and excellent corrosion resistance. Industries such as chemical processing and food production face several tangled issues related to material deterioration and performance when exposed to harsh environments. EOS NickelAlloy C22 has been tailored to address those challenges head on.

Key attributes of EOS NickelAlloy C22 include:

- Good resistance against corrosion from both biological and chemical media

- High strength and rugged toughness for applications under stress

- Tolerance to contact with aggressive environments

This alloy enables manufacturers to innovate faster and steer through supply chain hurdles and production delays, especially in fields where the risk of material degradation is a constant worry.

EOS Steel 42CrMo4: A Versatile Alloy for the Automotive and Mobility Sectors

The automotive industry has long relied on steel for its balance of strength and workability. EOS Steel 42CrMo4 brings the benefits of this familiar, traditional alloy into the realm of additive manufacturing. Renowned for its high toughness and strength, this low-alloyed steel is ideal for intricate parts such as gears, crankshafts, and connecting rods.

By adopting EOS Steel 42CrMo4, manufacturers can:

- Achieve lightweight design possibilities through faster development cycles

- Enjoy greater flexibility in supply chains

- Reduce the off-putting delays and nerve-racking risks associated with limited production capabilities

The cost-effective nature combined with its industry-standard performance makes this alloy a smart choice for engineers seeking to innovate in the challenging space of automotive and mobility solutions. Like EOS FeNi36, this alloy is compatible with EOS M 290 machines and is available commercially right now.

EOS StainlessSteel 316L-4404: A Robust, Industrial-Grade Stainless Steel

Moving into the arena of widely adopted stainless steels, EOS StainlessSteel 316L-4404 is a European industry-standard material variant that delivers high ductility, toughness, strength, and corrosion resistance. This alloy is crafted for applications in fields such as chemical processing, water treatment, food production, and marine applications.

The critical benefits include:

- Maintaining high performance at a lower cost compared to some standard alloys

- Compatibility with diverse systems – including the EOS M 290, EOS M 400, EOS M 400-4, and EOS M 300-4

- Being engineered to meet industrial-grade demands while staying true to the parameter sets familiar to professionals

This stainless steel variant is poised to simplify some of the complicated pieces of production planning in industries where durability and resistance to harsh chemicals or saltwater are essential.

Comparing the New Alloys: A Snapshot Table of Key Properties

| Alloy | Key Application Areas | Notable Features | Compatible Systems |

|---|---|---|---|

| EOS FeNi36 | Aerospace, Space, Defence, Energy | Ultra-low thermal expansion, high dimensional stability | EOS M 290 |

| EOS NickelAlloy C22 | Chemical Processing, Food Production | High corrosion resistance, exceptional toughness | EOS M 290 (initially) |

| EOS Steel 42CrMo4 | Automotive, Mobility | High toughness, cost-effective, industry-standard | EOS M 290 |

| EOS StainlessSteel 316L-4404 | Chemical, Water Handling, Marine, Food | High ductility, strong corrosion resistance, lower cost | EOS M 290, M 400, M 400-4, M 300-4 |

Advancing Additive Manufacturing: What Do These Alloys Mean for the Industry?

The introduction of these new alloys is not just a matter of expanding a product portfolio—it marks a significant leap forward in addressing the tricky parts of modern manufacturing. Today’s markets are often riddled with issues that stem from limited material choices, inconsistent performance, and off-putting supply chain vulnerabilities.

By broadening its materials portfolio, EOS is providing engineers and manufacturers with a much-needed tool to manage their way through these confusing bits of production planning. This development is particularly exciting because:

- Manufacturers can now choose an alloy that is precisely tuned to their application requirements.

- The increased portfolio helps reduce dependence on a single material, making companies less vulnerable when facing supply chain disruptions.

- The enhanced material properties open up new opportunities for design innovation and production efficiency.

Overcoming Challenging Supply Chains with Customized Alloy Solutions

One of the subtler elements in the conversation around additive manufacturing is how companies tackle a network full of confusing bits and nerve-racking supply chain challenges. EOS’s new offerings help address many of these issues. By providing alloys that have been optimized for specific performance criteria, the company makes it easier for manufacturers to:

- Reduce downtime in production by using readily available, purpose-made alloys.

- Adopt materials that are less vulnerable to the twists and turns of global supply chain issues.

- Ensure that even when faced with intimidating material shortages or delays, there remains an alternative that meets both technical and economic requirements.

For industries such as aerospace and chemical processing, where delays and performance inconsistencies can have a domino effect on production timelines, having a diverse materials portfolio is not just a competitive advantage—it is essential.

Addressing the Tricky Parts: Managing the Fine Points of Material Integration

Introducing a new material into a production line is not without its own nerve-racking challenges. There are several subtle details – including machine compatibility, process parameter adjustments, and quality assurance procedures – that need to be considered. EOS’s decision to optimize these new alloys for its Laser Beam Powder Bed Fusion (PBF-LB) systems speaks directly to the importance of smoothing out these little twists in the production process.

Some key points that manufacturers need to consider include:

- Process Validation: Ensuring that the additive process produces repeatable quality and meets stringent industry standards.

- Parameter Tuning: Adjusting laser power, scanning speed, and other process variables to get the best performance from the new materials.

- Integration with Existing Systems: Minimizing the need for new hardware investments by ensuring compatibility with current machines, like the EOS M 290, M 400, and others.

By thinking through these factors, manufacturers can manage their way through the intimidating side of material integration and move confidently toward using these innovative alloys.

Exploring Opportunities in Aerospace and Advanced Applications

Aerospace remains one of the largest beneficiaries of advancements in additive manufacturing. The exacting requirements of aircraft, satellites, and other high-performance systems call for materials that offer impeccable precision under extreme conditions. EOS FeNi36, with its outstanding thermal stability, is particularly suited to these applications. Its low coefficient of thermal expansion means that parts used in aerospace settings are less likely to suffer from thermal-induced distortions.

This directly translates to:

- Increased reliability of optical components such as mirror mounts and precision metrology equipment.

- Enhanced performance in cryogenic environments where temperature fluctuations can be particularly tricky.

- Improved design freedom as engineers can count on consistent material behavior over a range of temperatures.

Such breakthroughs allow aerospace manufacturers to innovate faster, address supply chain concerns, and ultimately reduce the nerve-racking uncertainties that often come with high-performance material requirements.

Automotive and Mobility: Fueling a New Era of Production Flexibility

The automotive sector is known for its fast-paced demand and the need for quick turnaround times in both design and manufacturing. EOS Steel 42CrMo4 offers an ideal solution for these industries, thanks to its well-balanced profile of high toughness and cost efficiency. As automotive engineers seek to find their way through complicated pieces of design and production, having a robust alloy that can be processed with existing AM technologies is a huge plus.

This material can help automotive designers in several ways:

- Lightweight Design: Allowing for the production of lighter yet strong components that reduce overall vehicle weight and improve fuel efficiency.

- Faster Development Cycles: Enabling rapid prototyping and streamlined production processes which shave off valuable time from traditional manufacturing techniques.

- Greater Supply Chain Flexibility: Minimizing dependency on parts that may be subject to long lead times or supply disruptions.

With such benefits, EOS Steel 42CrMo4 is positioned as a key enabler for innovation in the mobility space. It equips manufacturers with the tools to tackle those nerve-racking production delays and complexities head-on.

Industrial and Chemical Process Applications: The Role of Corrosion-Resistant Alloys

The chemical processing and food production sectors have long dealt with materials that are on edge due to exposure to corrosive chemicals, high humidity, or even biological media. EOS NickelAlloy C22 represents a critical breakthrough for these industries. Its design – anchored in high strength, superb corrosion resistance, and robust toughness – offers a safe harbor against the myriad of tiny issues that can add up to major production downtime.

Some benefits for chemical and industrial applications include:

- Minimized maintenance downtime due to fewer breakdowns caused by corrosive wear.

- Longer service life of parts especially when in constant contact with aggressive substances.

- Enhanced safety and regulatory compliance thanks to reliable material performance under stress.

These features make EOS NickelAlloy C22 particularly appealing for applications where material degradation has been a longstanding, off-putting problem. Manufacturers can now take a closer look at how carefully choosing an alloy can significantly impact overall productivity and operational reliability.

Economic and Supply Chain Implications of a Diversified Material Portfolio

Beyond the individual merits of each alloy, EOS’s overall strategy to expand its materials portfolio offers broader economic benefits. By providing a more comprehensive range of materials that are optimized for established AM systems, the company is addressing supply chain challenges that many industries face today.

Some of the key economic and production-related advantages include:

- Reduced production lead times due to easier access to precisely tailored materials.

- Lower costs associated with material waste and downtime, as engineers can more accurately predict material behavior.

- Greater flexibility across multiple production lines with standardized, yet specialized materials.

- Enhanced competitiveness in global markets, as companies are no longer held back by limited material choices.

In an economic landscape that is sometimes tangled with supply chain disruptions and off-putting delays, these improvements are super important in establishing resilience and agility. Manufacturers benefit from reduced risks and increased efficiency by leveraging a diversified alloy strategy.

Addressing Production Challenges: The Fine Points of Implementation

Rolling out new materials is never a straightforward process. There remain several hidden complexities in how these alloys must be integrated into existing additive manufacturing workflows. Manufacturers must carefully dig into the practical aspects of implementation, including:

- Recalibrating laser settings to handle different melting points and thermal behaviors.

- Training technical staff on the slight differences when processing each material.

- Ensuring post-processing techniques are adjusted to accommodate new surface properties.

- Working through quality assurance and certification challenges to meet industry standards.

Each of these nitty-gritty details represents a set of challenges that must be sorted out before the full benefits of the new alloys can be realized. However, the investment in overcoming these twists and turns is likely to pay off, as manufacturers gain access to a more reliable and flexible production environment.

The Big Picture: A Shift Toward a More Innovative Manufacturing Future

EOS’s recent expansion of its metal powder range signals more than just a product update—it hints at a strategic shift in the wider world of industrial production. As global markets continue to demand more customized and high-performance components, the ability to pick the right material for the right job becomes essential.

This shift is happening at the intersection of several important trends:

- Advancements in 3D printing technologies that are making it easier to bring complex designs to life.

- The increasing importance of supply chain resilience and cost management in rapidly changing global conditions.

- A growing emphasis on sustainable production and reducing material waste through precision manufacturing.

EOS’s new alloys empower manufacturers to move beyond the limitations of older materials. By offering solutions that are both innovative and compatible with existing production lines, EOS is enabling a smoother transition from traditional manufacturing methods to more cutting-edge additive processes.

Future Prospects: How the New Alloys Could Redefine Industry Standards

Looking ahead, the implications of EOS’s materials expansion are far-reaching. In the next few years, we can expect to see:

- Greater Adoption of AM Technologies: As more industries take advantage of the diverse properties offered by these new alloys, the role of additive manufacturing will continue to expand, paving the way for even more innovative applications.

- Enhanced Research and Development: Companies will likely invest more heavily in R&D to further optimize alloy compositions, tailor-making them for even more specialized uses.

- Improved Global Standards: The success of these materials might lead to updated industry standards and certifications, ensuring that quality and performance are maintained even as production methods evolve.

- Expanded Ecosystem Partnerships: With a broader portfolio, EOS and its partners are set to form new alliances with suppliers, research institutes, and end-users, strengthening the overall ecosystem of metal additive manufacturing.

This future-forward landscape is exciting not only for its technological promise but also for its capacity to reduce the risky, intimidating nature of change. As companies continue to poke around and take a closer look at advanced materials, the cumulative benefits—better performance, cost savings, and production efficiency—will soon become evident on a global scale.

What Industry Leaders Are Saying

Across the board, industry insiders have welcomed EOS’s new alloy line-up. Experts point out that the introduction of alloys like EOS FeNi36 and EOS NickelAlloy C22 has sparked conversations about how best to align material choices with specific project requirements. Some of the key sentiments include:

- “Adapting to these innovative alloys helps us figure a path through previously tangled issues in thermal management and corrosion resistance,” noted one aerospace engineer.

- “The availability of materials designed for standard AM systems like the EOS M 290 means we can reduce both downtime and the intimidating risk of retooling our entire production line,” commented a manufacturing director from the automotive sector.

- “Having cost-effective, industrial-grade options such as EOS StainlessSteel 316L-4404 is a major win for industries that deal with aggressive environments daily,” stated a chemical processing specialist.

Overall, leaders believe that EOS’s approach represents not only a bold step in product expansion but a carefully considered strategy designed to tackle the fine points and hidden complexities of modern production.

Expert Tips for Manufacturers Considering New Alloys

For manufacturers interested in harnessing the power of these new metal powders, here are some practical pointers to keep in mind:

- Start Small: Before fully integrating a new alloy into your production line, begin with pilot projects that let you fine-tune processing parameters.

- Focus on Training: Ensure that your technical teams are given the time and resources to get into the little details of processing each new material effectively.

- Collaborate with Experts: Work closely with suppliers and industry experts to understand potential pitfalls and best practices in adapting new alloy technologies.

- Monitor and Adjust: Use real-time monitoring tools to track performance, and be prepared to make adjustments as needed to optimize quality and efficiency.

Manufacturers who adopt these practical strategies are more likely to manage their way through the tricky parts associated with any technological shift. In the long run, the move toward these innovative alloys is expected to yield faster production cycles, reduced waste, and higher-quality outputs.

Conclusion: A Promising New Chapter in Metal Additive Manufacturing

EOS’s expansion of its metal powder range with EOS FeNi36, EOS NickelAlloy C22, EOS Steel 42CrMo4, and EOS StainlessSteel 316L-4404 is a major milestone for the additive manufacturing industry. By addressing the subtle parts of material performance—from thermal stability and strength to corrosion resistance and processing efficiency—these alloys help innovative companies find their way through the confounding twists and turns of production challenges.

In summary, this strategic move brings several advantages:

- A broader material palette that enhances design freedom and production reliability.

- More choices for specialized applications, reducing supply chain vulnerabilities and off-putting production delays.

- Improved compatibility with existing AM systems, thereby easing the adoption curve for advanced production techniques.

- A boost to overall industry innovation, which will likely set the stage for even more exciting breakthroughs in the years ahead.

As the metal additive manufacturing landscape continues to evolve, initiatives like EOS’s new alloy offerings are critical for building a more resilient, adaptable, and innovative future. With these new materials at their disposal, engineers and designers can move forward with greater confidence, knowing that the materials they rely on have been engineered to meet the most critical performance criteria.

Ultimately, whether you’re working in aerospace, automotive, chemical processing, or another industry loaded with its own tricky parts and nerve-racking production challenges, EOS’s latest expansion provides a robust set of tools that can help you dig into the future of manufacturing with optimism and clarity.

It is an exciting time for anyone invested in metals, manufacturing, and the broader industrial ecosystem. With careful preparation, smart partnerships, and a focus on managing the fine points of production integration, these new alloys could very well redefine industry standards. The journey ahead may be full of small distinctions and fine shades in production performance—but that’s where true innovation resides.

As we watch EOS and other innovators continue to shape the future of metal additive manufacturing, one thing is increasingly clear: the clever integration of advanced materials is not just a matter of technical improvement, but a strategic imperative that can help industries overcome supply chain hurdles, meet evolving market demands, and drive a more sustainable, efficient approach to production.

In this rapidly changing world, companies willing to figure a path through the train of challenging, sometimes intimidating production issues will emerge with a competitive edge. The recent expansion by EOS is a reminder that innovation often comes in the form of subtle, yet significant advances—advances that ultimately turn the tide in favor of smarter, more resilient manufacturing.

Originally Post From https://www.metal-am.com/eos-expands-its-metal-powder-range-with-four-new-alloys/

Read more about this topic at

EOS expands its metal powder range with four new alloys

EOS Adds Four New Metal Additive Manufacturing …