Transforming the Chemical Landscape with Renewable Isocyanates

The Renewable Isocyanate Market: An Opportunity to Redefine Chemical Sustainability

The global chemical landscape is undergoing a profound transition. The renewable isocyanate market, valued at approximately USD 38.1 million in 2025 and forecasted to escalate to over USD 611.7 million by 2035, stands as a testament to the shift toward environmentally friendly and sustainable chemical solutions. In today’s opinion editorial, we explore the currents driving this market’s meteoric rise, the benefits these renewable chemicals bring, and the tricky parts manufacturers and policymakers must contend with. The discussion takes a closer look at factors ranging from technology innovation to government incentives, all set against the backdrop of increased environmental awareness.

Riding the Wave of Bio-Based Innovation

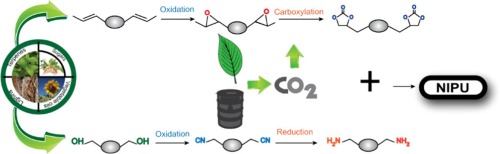

One of the most exciting developments in the chemical manufacturing world is the emergence of bio-based methylene diphenyl diisocyanate (MDI) as a dominant product. Capturing 42.3% of the renewable isocyanate market share, bio-based MDI is pushing the envelope in sustainable chemical production. Manufacturers are increasingly leaning into bio-based solutions, spurred by the promise of reduced carbon footprints and enhanced performance in high-demand polymer applications. This shift is not just a fleeting trend—it is reconfiguring the very way the industry thinks about raw materials and environmental compliance.

Environmental Benefits and Sustainable Manufacturing

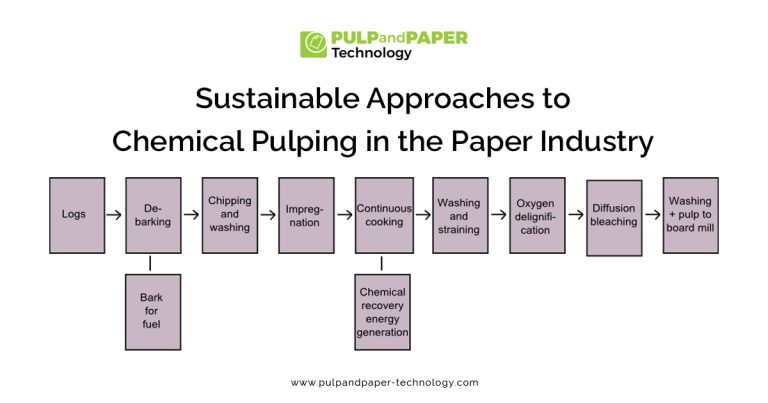

The move to renewable isocyanates reflects a broader environmental movement in chemical production. Companies are now prioritizing materials that offer superior environmental credentials while simultaneously delivering on performance. The use of renewable feedstocks, such as plant-based oils, agricultural residues, and recycled carbon sources, underscores the commitment to processes that are less reliant on fossil fuels. This change has notable implications:

- Reduced carbon emissions from production facilities.

- Mitigation of dependence on non-renewable resources.

- Improved sustainability profiles that appeal to environmentally conscious consumers.

- Alignment with increasingly strict government regulations and environmental standards.

By integrating these renewable ingredients into polymer production, manufacturers are not only tapping into growing global demand but also ensuring that their processes reflect modern environmental priorities, making these developments both commercially and ecologically essential.

Examining the Upsides in Rigid Foam and Beyond

Rigid foam production remains the primary application driving market growth, with a projected share of 35.6% in 2025. As demand for rigid foam rises in sectors like construction and insulation, manufacturers are leveraging the unique properties of renewable isocyanates to produce foams that are both high-performing and sustainable. This shift is proving especially beneficial in industries where maintaining structural integrity is critical, such as automotive components and industrial packaging.

Sustainable Production in Rigid Foam Applications

The rigid foam segment embodies the potential benefits of renewable isocyanates in several key areas:

- Enhanced Structural Integrity: Renewable isocyanates offer excellent polymerization properties that translate into rigid yet resilient foam materials.

- Improved Environmental Profile: With reduced reliance on non-renewable chemicals, these foams provide insulation solutions that align with green building practices.

- Cost-Effective Production: Advances in bio-production methods are gradually reducing costs, making it increasingly viable for mass production.

Manufacturers not only gain from a sustainable raw material base, but they can also market these innovative foams as part of broader efforts to reduce energy consumption and environmental impact in construction and industrial applications.

Global Market Trends: A Regional Perspective

The renewable isocyanate market is experiencing explosive growth in several key regions. With international players like BASF, Covestro, and Wanhua Chemical setting benchmarks for performance and innovation, regional dynamics are equally intriguing. For instance, China is projected to lead the market with an impressive 43.2% CAGR through 2035, while India follows closely with a 40.0% CAGR.

Regional Growth Drivers and Opportunities

Different regions offer unique advantages and challenges:

- Asia Pacific: Rapid industrialization and supportive government policies fuel robust market growth. Advanced bio-production technologies and an ever-increasing demand for sustainable chemicals contribute to a positive outlook.

- North America: With a strong emphasis on regulatory compliance and technological integration, North American markets are steadily increasing the adoption of renewable isocyanate systems, supported by investments in production optimization.

- Europe: Mature chemical markets in countries like Germany, the United Kingdom, and France reveal a readiness to pivot toward renewable resources, driven by stringent environmental regulations and a commitment to sustainable manufacturing processes.

These regional comparisons allow industry stakeholders to appreciate the subtle details that define local market dynamics. For instance, while North America focuses on advanced technology integration, Asia Pacific benefits from large-scale industrial expansion and resource advantages, making a compelling case for diversified regional strategies.

Facing the Tricky Parts: Production and Regulatory Challenges

Although the renewable isocyanate market is brimming with opportunities, manufacturers and policymakers must also contend with some tangled issues. The shift to renewable methods comes with its share of technical and regulatory challenges that can be both intimidating and overwhelming. These include:

- Production Scale Limitations: The current bio-production technologies, though promising, often face constraints in achieving commercial-scale outputs.

- Feedstock Availability and Cost Volatility: While renewable feedstocks offer environmental benefits, they can also be subject to fluctuations in supply and cost, particularly when sourced from agricultural residues or waste sources.

- Regulatory Hurdles: Navigating policy frameworks that favor traditional chemical processes over more environmentally sound alternatives can be nerve-racking for new and established players alike.

Manufacturers find it essential to get into these challenging bits head-on by investing in research and development. Maturing bio-production processes and developing integrated production systems are key steps in ensuring that these hurdles do not stifle the market’s potential. As the industry makes its way forward, working through these production and regulatory issues will be critical for achieving scalable success.

Government Policies and Circular Economy Incentives

Government policies play a critical role in shaping market directions, especially in industries riddled with regulatory twists and turns. Globally, policymakers are increasingly recognizing that targeted incentives—ranging from production subsidies to research and development grants—can significantly stimulate the adoption of renewable isocyanate technologies.

Key Policy Measures to Foster Market Growth

Several policy initiatives can help spur local production and adoption:

- Bio-Based Manufacturing Subsidies: Direct financial incentives for companies transitioning to renewable isocyanate production can lower perceived risks and encourage greater investments in new technologies.

- Trade Facilitation Protocols: Simplifying export and import regulations under the banner of sustainable, bio-based chemicals will help companies more easily access international markets.

- Establishing Innovation Centers: Governments can set up Centers of Excellence focused on bio-based chemical research, providing shared resources, technical expertise, and incubation programs for emerging technologies.

These measures are not just theoretical. Real-world examples indicate that regions embracing circular economy principles and fostering integrated bio-refinery systems are better positioned to reap both economic and environmental dividends in the long run.

Innovation and Advanced Production Technologies: Steering Through New Frontiers

The renewable isocyanate market is marked by significant leaps in technology, with companies racing to refine production methods and improve product performance. Advanced processes—from bio-catalytic methods to fermentation-based techniques—are key to meeting the growing demand for premium, renewable isocyanate grades that exhibit superior reactivity and processing compatibility.

Technological Breakthroughs Driving Market Competitiveness

Several technological strategies are now at the heart of market expansion:

- Hybrid Production Systems: By blending traditional chemical conversion with bio-based methodologies, these systems create a balance between scale and sustainability.

- Advanced Feedstock Conversion: R&D investments in optimizing feedstock conversion are producing renewable isocyanates with enhanced cost-effectiveness and chemical performance.

- Quality Monitoring and Automated Controls: Integration of advanced quality monitoring ensures that chemical functionalities remain uncompromised even as production scales up.

These innovations are encouraging a broader adoption of renewable isocyanate systems. Manufacturers are now less afraid to experiment with novel techniques, given the substantial improvements in process efficiency and product consistency. As a result, industry leaders and new entrants alike are increasingly eager to take advantage of these technological breakthroughs to secure a competitive edge in an evolving market.

Challenges in Scaling and the Need for Strategic Partnerships

While the potential benefits of renewable isocyanates are evident, scaling production remains a tricky part. The path from pilot projects to full-scale production is often loaded with issues that, if not managed appropriately, could hinder progress. However, there is a bright side: strategic partnerships between government bodies, industry associations, and companies are proving invaluable in overcoming these hurdles.

Key Collaboration Strategies to Overcome Production Obstacles

Here are some approaches that are making a significant impact:

- Joint R&D Ventures: Companies are increasingly pooling resources and expertise to reduce costs associated with innovative production methods. This collaboration helps lower the initial financial burden and makes the scaling process less nerve-racking.

- Public-Private Partnerships: By leveraging government support and private sector ingenuity, partnerships can help create a more conducive environment for bio-based manufacturing to thrive.

- Industry Consortia: Forming coalitions with other players in the renewable chemicals sector creates tighter integration within the supply chain, fostering shared best practices and facilitating smoother market transitions.

These alliances also help manage the various regulatory and operational twists and turns that can otherwise deter individual companies from investing heavily in new technologies.

Understanding the Fine Points of Market Integration

The integration of renewable isocyanates into traditional chemical processes is not without its fine points. Manufacturers must address the subtle parts of product formulation and processing. For instance, ensuring that renewable isocyanates perform consistently across various polymer applications is a challenge that requires meticulous attention to technical specifications and customer requirements.

Managing the Little Details for Optimal Performance

In managing your way through the integration process, consider these critical elements:

- Chemical Functionality: Manufacturers must maintain the established chemical performance benchmarks while experimenting with new production techniques. This involves a deep dive into the little details of reaction kinetics and polymer compatibility.

- Product Quality Standards: Consistency in quality is paramount. Building advanced purification systems and quality controls into the production line can help preserve performance characteristics and ensure long-term customer satisfaction.

- Cost Competitiveness: Continuous innovations in production efficiency can help mitigate potential price increases that might arise from switching to renewable feedstocks. This balance between quality and cost is critical for market acceptance.

Overall, manufacturers looking to make the transition must be ready to invest in research, technology upgrades, and comprehensive quality assurance systems to ensure that they are delivering products that meet both environmental and performance standards.

Evaluating the Impact on Downstream Industries

The ripple effects of advancements in renewable isocyanate technology are being felt across a wide range of industries. For example, automotive manufacturers, furniture producers, and packaging solution providers all stand to benefit from polymer systems that are not only high-performing but also have a lower environmental impact. The integration of bio-based isocyanates into coating formulations, adhesives, and elastomer products is influencing multiple sectors simultaneously—prompting a reevaluation of supply chains and production techniques that were once considered conventional.

Benefits for Consumer Products and Industrial Markets

Some of the major benefits include:

- Improved Environmental Compliance: Adoption of renewable isocyanates helps companies meet regulatory requirements and achieve certifications that appeal to eco-conscious customers.

- Enhanced Product Differentiation: Companies using sustainable inputs can market their products as environmentally friendly alternatives, thereby standing out in competitive markets.

- Operational Efficiency: By harnessing advanced production techniques, manufacturers can achieve better resource utilization, which, in turn, results in lower waste and improved cost efficiency.

As different industrial sectors continue to adapt to greener practices, the market uptake for renewable isocyanates is expected to grow, reinforcing the move toward more sustainable industrial practices.

The Role of Industry Leaders in Shaping Market Direction

Industry titans such as BASF, Covestro, Mitsui Chemicals, and Wanhua Chemical are not only setting performance benchmarks but are also instrumental in redefining the market’s competitive landscape. Their continued focus on R&D, production optimization, and market expansion is demonstrating that the transition to renewable isocyanates is not merely a trend but a lasting industrial revolution. These companies are exploring various approaches, from adopting hybrid production technologies to establishing integrated bio-refinery systems, all aimed at creating a robust and scalable market ecosystem.

Strategies for Sustaining Market Leadership

Key strategies employed by top players include:

- Investment in Research and Development: Continuous R&D drives innovation in product formulations and production methods, ensuring that renewable isocyanates can meet evolving performance and regulatory demands.

- Building Robust Supply Chains: An integrated approach to sourcing renewable feedstocks and implementing advanced production controls is crucial for maintaining product quality and cost-effectiveness.

- Market Diversification: Expanding applications across diverse sectors—ranging from rigid and flexible foams to coatings and adhesives—helps spread risk and creates multiple channels for revenue growth.

By taking these proactive measures, industry leaders are not only growing their market share but also setting the stage for broader industry adoption. Their efforts underscore the importance of strategic foresight in a market that is evolving as quickly as renewable isocyanates.

Addressing the Overwhelming Production Challenges

Despite the promising outlook, the journey toward high-volume production of renewable isocyanates remains full of problems. The hurdles associated with scaling up experimental processes, along with managing the fine points of quality control, can be both intimidating and complex. However, industry players are making steady progress by refining production techniques and forming strategic alliances that ease the nerve-racking transition from lab-scale experimentation to commercially viable production.

Overcoming Production Limitations Through Collaboration

Practical approaches to address these production hurdles include:

- Enhancing Process Efficiency: Companies are investing in advanced automation and quality monitoring systems to ensure consistent product quality as production scales up.

- Standardizing Production Protocols: Streamlining production methodologies can help reduce variability, making it easier to replicate laboratory successes in large-scale operations.

- Resource Sharing: Collaborative ventures and consortia are enabling smaller players to access state-of-the-art technologies and economies of scale that would otherwise be out of reach.

Such initiatives not only pave the way for resolving immediate production issues but also create a foundation for long-term sustainability and market resilience.

Looking Ahead: Future Predictions for the Renewable Isocyanate Sector

Market forecasts suggest an explosive growth trajectory, with the renewable isocyanate market expected to grow over 16 times its 2025 size by 2035. This projection is fueled by the increasing demand for renewable feedstock materials, the rising integration of circular economy principles, and the advancement of commercial-scale production technologies. Looking into the future, several key trends are likely to shape this market:

Key Trends Shaping the Future Landscape

Let’s take a closer look at some of the major emerging trends:

- Integration of Circular Economy Principles: Continuous emphasis on reducing waste and optimizing raw material usage will drive the development of closed-loop systems in chemical production.

- Adoption of Premium Grade Renewable Isocyanates: As manufacturers look for products that offer enhanced reactivity and processing compatibility, the demand for specialized, high-quality renewable isocyanates will increase.

- Advancements in Bio-Refinery Technologies: To achieve large-scale production, further innovation in integrated bio-refinery systems is critical, ensuring that renewable isocyanate production is both efficient and cost-effective.

- Focus on Environmental and Economic Sustainability: With a dual emphasis on meeting strict environmental guidelines and maintaining economic viability, the industry will continue to innovate and refine its production approaches.

These trends indicate that the renewable isocyanate market is set for sustained expansion—even as it addresses production challenges and adapts to evolving environmental policies. Stakeholders who can figure a path through these dynamic conditions, while taking advantage of the latest technological advances, will be well-positioned to lead in this emerging frontier.

Strategic Recommendations for Market Participants

For those entrenched in this sector or considering entering, taking strategic, forward-thinking steps is super important. In our opinion, companies must invest in robust research, commit to process improvements, and actively participate in industry consortia to leverage collective expertise. Here are some recommendations for market participants:

- Invest in Technology: Prioritize research into advanced bio-catalytic and fermentation-based production methods. Staying ahead of the technological curve will ease many of the complicating twists and turns of scaling up production.

- Forge Strategic Alliances: Aligning with other industry leaders through joint ventures or public-private partnerships can help spread the risk and cost of innovation while easing the pathway to market expansion.

- Enhance Quality Controls: Implement state-of-the-art quality monitoring systems to ensure chemical consistency and meet ever-stricter regulatory requirements. High product quality will help win customer trust, especially in competitive markets.

- Diversify Applications: Explore new sectors or applications where the environmental benefits of renewable isocyanates can serve as a unique selling point. Whether it’s for automotive components, furniture manufacturing, or advanced packaging solutions, diversification opens up numerous revenue streams.

- Engage with Policy Makers: Actively participate in policy discussions and industry forums. Influencing regulatory frameworks and securing government incentives can dramatically improve market conditions.

By following these strategic recommendations, companies can get around many of the overwhelming production and regulatory issues, positioning themselves to capitalize on the market’s impressive growth potential.

The Bigger Picture: An Ecosystem in Transition

At its core, the renewable isocyanate market exemplifies the broader global push towards sustainability and efficiency. The high-growth expectations, combined with steadily changing environmental policies and evolving technological capabilities, illustrate a significant shift in industrial practices. This transition is not limited to the chemical sector alone; downstream industries—from automotive to construction—are benefiting from the ripple effects of this green revolution.

How the Ecosystem Benefits from Renewable Isocyanates

An integrated approach to environmental innovation provides a triple win for stakeholders:

- Environmental Impact: Reduced carbon intensity and enhanced use of renewable feedstocks contribute significantly to lowering the overall environmental footprint of industrial operations.

- Economic Growth: The burgeoning market size, combined with new export opportunities and the creation of jobs in advanced manufacturing sectors, bodes well for economic growth across multiple regions.

- Technological Advancement: Continuous innovation in production processes and quality control helps drive advances in related sectors, ultimately improving the efficiency and sustainability of the supply chain.

This interconnected ecosystem reveals a future in which each stakeholder—from government bodies to private companies—plays a key role in redefining what industrial sustainability looks like. For the renewable isocyanate sector, these collaborative dynamics are likely to be a driving force in maintaining market momentum over the next decade.

Conclusion: A New Era for Sustainable Chemicals

The renewable isocyanate market stands on the precipice of a new era. As manufacturers transition to more sustainable, bio-based solutions, the entire chemical industry faces an exciting transformation that promises environmental, economic, and technological advantages. While the journey is replete with tricky parts and occasional overwhelming hurdles, the collective efforts of innovators, policymakers, and industry leaders are steering the market toward a brighter, greener future.

From the rapid growth in regions like Asia Pacific and North America to the significant investments in advanced production technologies, the renewable isocyanate market is more than just a niche development—it is a cornerstone of future industrial progress. Those who take the time to figure a path through the fine points of production challenges and regulatory landscapes will lead the way in sustainable polymer manufacturing, setting new benchmarks for environmental stewardship and economic innovation.

As this vivid transformation continues, the key for companies and stakeholders alike will be to remain agile, continuously innovate, and prioritize both performance and environmental harmony. The renewable isocyanate market is not just evolving; it is reshaping the future of chemical production and creating spaces for unprecedented opportunities in the global marketplace.

In the coming years, as bio-based technologies mature and the world leans more toward sustainable solutions, the insights shared here serve as a reminder that while the road may sometimes be riddled with tension and confusing bits, persistence and strategic collaboration will ultimately yield a more sustainable, economically robust future for all.

Originally Post From https://www.futuremarketinsights.com/reports/renewable-isocyanate-market

Read more about this topic at

Algenesis cracks diisocyanate problem to make fully bio- …

Bio-based Isocyanate Market Size | Industry Report, 2030